The PartsBadger Blog

Stay up to date with news and highlights about PartsBadger and our industry.

Difference Between Drilling and Tapping

Drilling and tapping are both processes that involve using specific cutting tools to remove metal from an object in order to create either a threaded hole or simply a smooth hole in the object’s surface.

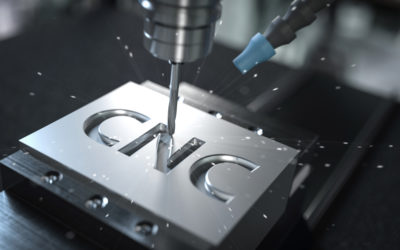

3D Milling – A Complete Guide

3D milling machines, also known as CNC machining centers, are computer-controlled tools used to create complex parts from raw materials like plastic, wood and metal.

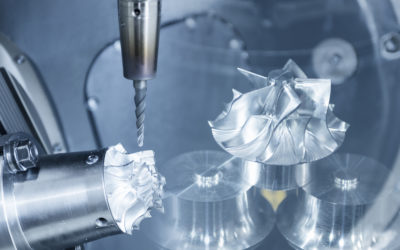

What is 5 Axis Milling

What is 5 Axis Milling? When it comes to machine tools, five-axis milling refers to milling machines that have the ability to machine in three dimensions and can also rotate on their own axis. A typical five-axis milling machine allows you to mill complicated shapes...

PartsBadger Hire New QC Lead

Parts Badger Hire New QC Lead Parts Badger has hired a new QC Lead in January to expand the business. Kris Haessler will take charge of creating quality products for customers. He will manage hard gaging, programming the CMM, putting quality procedures in place, and...

Differences Between 3, 4, and 5 Axis Milling

The differences between 3 axis milling, 4 axis milling, and 5 axis milling can be confusing at first, so we’ve created this guide to help you understand how each one works and which one will best suit your needs.

Waterjet Milling Guide

Waterjet milling, also known as hydro milling, involves the use of high-pressure water mixed with abrasive grains or particles to perform machining tasks and shape materials. Waterjet mills offer some distinct advantages over conventional milling tools, such as high...

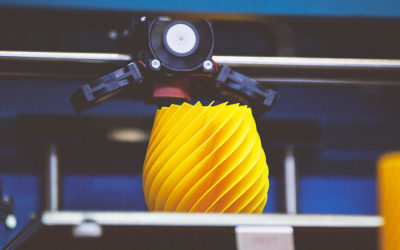

FDM 3D Printing Benefits

FDM 3D Printing Benefits An FDM (Fused Deposition Model) 3D printer is a tool that creates rapid prototypes through filaments. 3D printing is an additive manufacturing process, which is the complete opposite of a subtractive process. FDM 3D printers use filaments, or...

3D Printed Applications Guide

Today, there are a myriad of 3D printed applications across different industries that allows businesses to create products that would be difficult or impossible to make otherwise.

Parts Badger Adds New Collaborative Robot for Automated Manufacturing

Parts Badger is now investing in innovative manufacturing with new collaborative robot technology for machine tending. This collaborative robotic arm will complete milling jobs in their manufacturing facility. To keep up with supply chain demand, Roy Dietsch, CEO of Parts Badger, made the decision to innovate by investing in new technology for their machine shop.

SLA 3D Printer Applications

The SLA 3D printer applications are so popular that they can be spotted without knowing it. The printer is so great at details, that they look like regularly made objects. This is why so many industries use the oldest 3D printing technique.

Recent Comments