Types of Machining

PartsBadger offers a number of different machining methods to create your parts. Using a wide variety of machines PartsBadger is able to create simple and complex parts at the required tolerance and the best possible price.

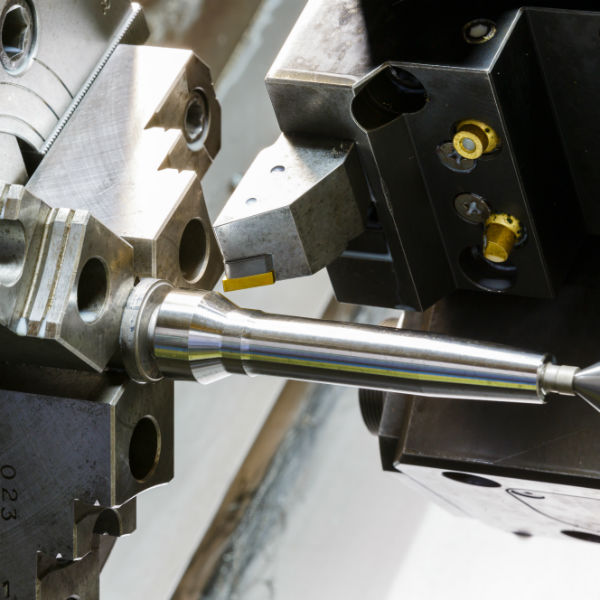

Turning

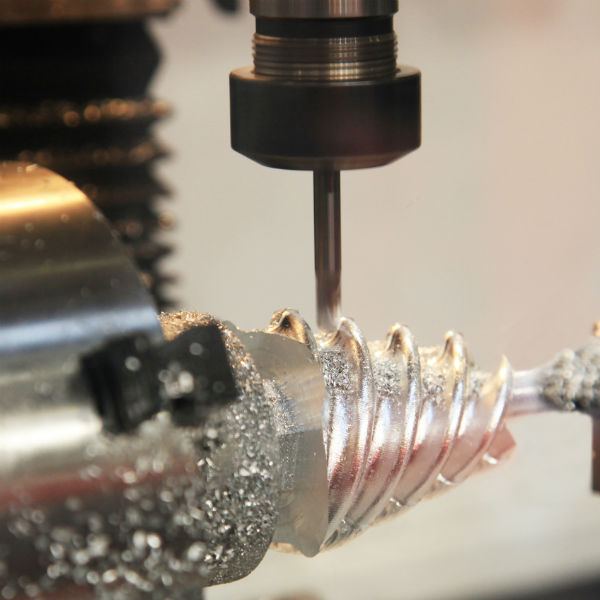

Swiss Machining

Swiss machining is a specialized manufacturing technique with the ability to produce high-quality, precise parts with incredible accuracy and speed.

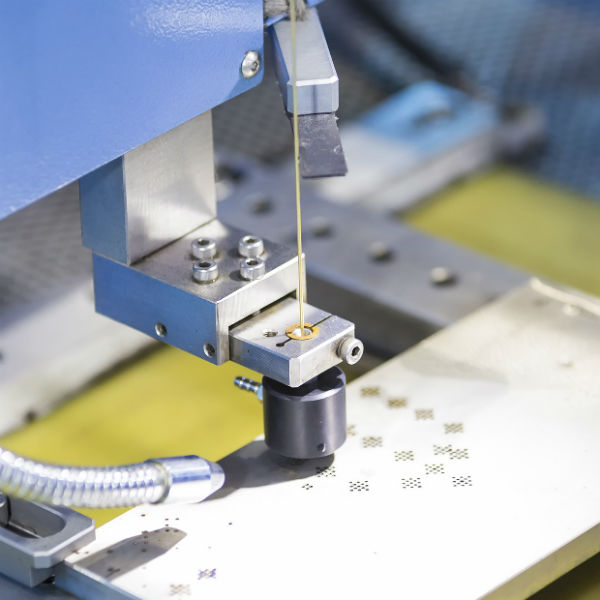

Wire EDM

Small Hole EDM

Sinker EDM

Accelerate Your Innovation

We’re here to help you manufacture your machined parts efficiently and timely. We understand the importance of getting your product(s) to market before your competitors do. We provide quotes in hours and most parts in 14-Days or less. Use the form to reach our specialists to request a quote, check on an order status, or to learn more about us and our capabilities. We’re ready to accelerate your innovation.