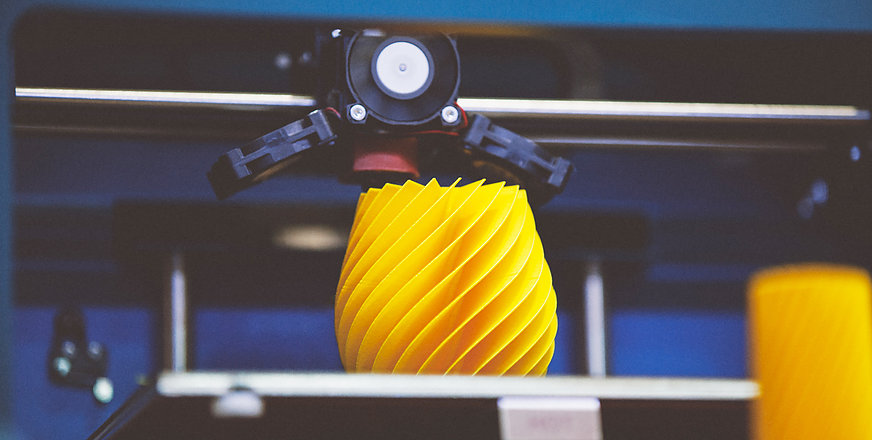

FDM 3D Printing Benefits

An FDM (Fused Deposition Model) 3D printer is a tool that creates rapid prototypes through filaments. 3D printing is an additive manufacturing process, which is the complete opposite of a subtractive process. FDM 3D printers use filaments, or molten plastic, to create layers for the 3D objects. This is much different than SLA 3D printing, which dips the product and uses a laser for layering. With this style of printing there are many benefits. It is much more customizable with the different types of plastics and affordable. There are other FDM 3D printing benefits.

Variety of Customizations

As mentioned above, a human being is known for his innovative ideas and boundless imaginations. Sometimes, our imaginations get restricted by the tools we use and we have to make compromises in the final product. However, if you are using Fused Deposition Modeling, there is no limit to customizations. In simple terms, if you can imagine something then, FDM can print it. Additionally, in FDM, you don’t have to change the printing chamber with changing end products. This means that you can customize your products according to the demands of your customer without incurring any extra expenses. This is one of the major FDM 3D printing benefits.

Goodbye to all Manufacturing Complexities

Certain parts are difficult to make with physical manufacturing processes and completely impossible to make with bare hands. This problem is prevalent in industries that demand sophisticated parts with utmost perfection. A major example of one such industry is aerospace research. FDM helps to make all sophisticated parts with utmost perfection to ensure that they stand to the expectations of the end-user. Additionally, all the parts that FDM makes are lighter and more durable than any other competitor. Many prominent companies such as intel have shifted all the major manufacturing processes to FDM due to these advantages of FDM 3D printing.

Tool-less Manufacturing Process

A lot of tools are involved in all physical manufacturing processes. Here, you will require different tools for every step of manufacturing. However, with FDM, you just need a printer and the digital model for all of your manufacturing processes. Fused Deposition Modelling can adjust itself according to the different modes of the fabrication process. FDM will seem to be a very costly investment in the initial phase but the companies must not overlook all the FDM 3D printing benefits. With passing years, FDM will help any company to save a fortune in the production expenses.

Environment-Friendly Products

Rapidly growing industrialization has heavily blessed our lives but completely devastated the environmental cycle. FDM uses thermoplastic polymer to make most of the products and this is a special high-quality plastic. This polymer has high reusable abilities and is completely recyclable. Additionally, FDM uses 90% of the raw material and produces minimal waste. Thus, we can conclude that this is one of the best production processes s it poses almost no threat to the natural balance. FDM allows all companies to make any item locally thus, it saves a lot of expenses that would be lost in shipping.

Reasonable Pricing and Consumes less time

All the parts of FDM which include printer, ceramic, and thermoplastic are very economical and very helpful to small start-up businesses. Additionally, the replacement parts of FDM printers don’t require too much investment and are very easy to install. This is one of the major advantages of FDM 3D printing.

One of the major FDM 3D printing benefits is its time effectiveness. For instance, FDM is capable of printing simple objects in half a day and more complex objects in just under a day. So, it is one of the fastest production processes in the entire industrial sector. Many companies like Intel are shifting their entire product range to FDM.

Broad Range of materials

FDM uses a huge range of materials for printing. So, companies can change the material for printing very easily without harming the production expenses. Additionally, they can use multiple materials at the same time to create complex structures very easily. Thus, FDM is the most flexible form of 3D printing.

Easy to Learn

A survey suggests that FDM is one of the easiest to learn 3D printing technologies. There are various types of 3D printing techniques but people tend to pick up on this technique pretty fast and also carry it out easily. So, this technique is very useful to companies that have no or very limited experience in 3D printing.

Conclusion

FDM 3D printers were made to be simple and easy to use. Various industries, including aerospace, automotive, civil engineering, dental, medical and many more, are using FDM 3D printing to increase their needs. It has a myriad of uses and applications that makes it useful to all walks of life.

Though there are still some challenges and limitations to using 3D printers in certain areas, they have come a long way from where they first started. Here at Parts Badger we specialize in quality parts need. Parts Badger creates your exact designed product. We use Instant quoting and 24/7 manufacturing to get your products created and back to you very quickly. Click here to request a quote for 3d printed parts.

Recent Comments