3D Printed Applications Guide

What is 3D printing? 3D printing, also known as additive manufacturing, is any process of making a three-dimensional solid object of virtually any shape from a digital model. Today, there are a myriad of 3D printed applications across different industries that allows businesses to create products that would be difficult or impossible to make otherwise.

Between SLA, DLP, and many more 3D printing, there are many different industries that use 3D printing. It’s easy to see why many companies are already taking advantage of it in their business operations – here are just some of the ways 3D printing can add value and improve your business today.

Throughout this guide, if you have any part needs, click here to request a quote with us and see what we can do for you.

Medical Devices

According to a report published by BCC Research, roughly $13.4 billion was spent on healthcare-related 3D printing in 2014. That number is expected to increase substantially over the next few years. Although it’s impossible to accurately project how quickly 3D printing will enter different industries, experts are starting to see an uptick in adoption.

Healthcare is likely to be one of those industries—especially considering some of its unique challenges when it comes to manufacturing and quality control. With 3D printing technology, however, patients could soon have access to 3D printed organs that match their blood type. While this application might seem high-tech and futuristic now, medical researchers say they’re just scratching the surface of what’s possible.

According to Pharmaceutical-Technology.com, pharmacists use 3D bioprinting to create living human cells or tissue for use in regenerative medicine and tissue engineering. With demand for critical medical equipment and supplies mounting from COVID-19, the ease of creating this equipment through 3D printing is highly beneficial. Discover how Parts Badger serves the Medical field.

Dentistry

Using a 3D printer to make dental retainers is an excellent 3D printer application. The high detail involved with dental retainers cannot be accomplished using traditional methods. However, due to their small size, it would take too long to traditionally print them out. By using a 3D printer, it takes only minutes and results in a precise fit every time! Dentists have been using 3d printers for years now. Their uses are countless.

From smile makeovers to medical assisting solutions. When you think about it, dentistry deals with all sorts of problems on a daily basis. This makes dentistry one of the industries that can really use some advancements in technology. With that being said, dentistry is one industry that has taken hold of 3D printing. It’s just another tool within their reach. A way for them to bring new life back into smiles or solve health issues faster than ever before!

Audiology

3D printing technology is a great asset to any audiology practice. Custom earplugs are easy to make on a 3D printer and have many different uses from everyday hearing protection at work to preventing swimmer’s ear.

3D printed hearing aids can be designed to fit perfectly into your ears, meaning no more hassle from untimely repairs or ill-fitting devices. Using an online database of average human head dimensions (similar to those used by shoe companies), it’s also possible to design custom hearing aids that mold directly to your ear canal.

Your audiologist will then file down and polish your new device so that it fits snugly inside of you. It won’t come loose during normal daily use or when diving underwater in swimming pools.

Consumer Goods

Companies are beginning to use 3D printed applications to improve their consumer goods products and supply chains. Using additive manufacturing, or AM, allows companies to make customized products in small batches. This reduces inventory costs and waste.

This capability is especially useful when dealing with consumers’ expectations of exactly how they want their product. Nervous about getting a size wrong? With AM, you don’t have to worry about having incorrect sizes cluttering up your warehouse. The 3D printer can just produce them on demand. Discover how Parts Badger serves the Consumer Goods industry.

Agriculture

3D printers can create physical models that help illustrate how different plants grow and thrive at different temperatures. Plus, through using computer-assisted design software, individuals can change any part of a model to reflect their needs.

The biggest benefit here is time. Instead of needing to plant hundreds of crops every year and then waiting months for harvesting, farmers could wait several years between crop growth cycles but harvest from a single 3D printer continuously.

Construction

The construction industry has been extremely slow to adopt 3D printing technology, but that’s rapidly changing. Why wouldn’t it? On a construction site, everything from blueprints to building materials is more expensive and time-consuming to transport. Once things are printed in place, production can move much faster. This creates print-on-demand manufacturing than traditional construction methods.

Plus, on-site fabrication means fewer workers need transportation to get their jobs done. In a country with as many aging roads as we have, that last one might be priceless. For further reading, check out our list of reasons why 3D printing will revolutionize construction.

Architects and designers are beginning to embrace 3D printing technology as a way to create mockups of their designs. Because 3D printers can print just about anything you can imagine, these prototypes are especially helpful when it comes to visualizing how different colors, shapes, and textures would look in real life. Discover how Parts Badger serves the Construction and Manufacturing industries.

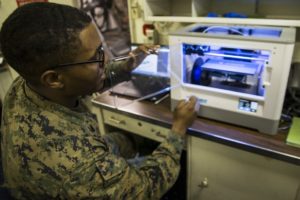

Military

3D printing can make a huge difference on battlefields by allowing soldiers to print up replacement parts and prototypes on-demand. The U.S. Army has been a big proponent of 3D printing, looking into everything from autonomous helicopter drones to flight-ready wings . Most recently, it has announced that it plans to be entirely self-sufficient in their production of spare parts within two years’ time. This will significantly cut down on logistics costs.

On top of spares, military forces are experimenting with printing weapons and surveillance drones. For example, the US Army is investing heavily in additive manufacturing technology to create custom weaponry. They will eventually settle on a multi-material grenade launcher designed with CAD software. Discover how Parts Badger serves the Military industry.

Aerospace

3D printing is a key part of making and building planes, helicopters, rockets, and spaceships. The engineers use the technology to make small parts like nose cones as well as major components like wing panels. Because 3D-printed parts are lighter than traditional ones, air travel becomes more energy efficient. But in aerospace, 3D printing has also been used for testing parts before full production.

For example, companies can use 3D printers to test designs or simulate difficult conditions at a much lower cost than creating physical models. Plus, because printed objects are made from metal powders rather than sand or other substances traditionally used in construction materials, they can be stronger and better prepared for real-world conditions. Discover how Parts Badger serves the Aerospace industry.

Automotive

Imagine auto manufacturers and garages being able to build 3D models of a car or engine, then send them directly to a machine to create. Engineers could print Car parts on demand, and easily replace broken down items.

The automotive industry is a big player in industrial 3D printing, which makes sense since a car needs dozens of intricate parts that need to perfectly fit together. As it turns out, building parts in tiny layers with additive manufacturing is much more efficient than traditional metal fabrication or other methods. Discover how Parts Badger is revving up the automotive industry.

Conclusion

Various industries, including aerospace, automotive, civil engineering, dental, medical and many more, are using 3D printing to increase their needs. It has a myriad of uses and applications that makes it useful to all walks of life.

Though there are still some challenges and limitations to using 3D printers in certain areas, they have come a long way from where they first started. Here at Parts Badger we specialize in quality parts need. Parts Badger creates your exact designed product. We use Instant quoting and 24/7 manufacturing to get your products created and back to you very quickly. Click here to request a quote for 3d printed parts.

Recent Comments