Parts Badger is now offering 3D Printing services to all their customers. After receiving many inquiries about the service, Roy Dietsch, CEO of Parts Badger, made the decision to expand their capabilities to 3D printing.

“Prototyping and On Demand production through 3D printing gives another tool to drive innovation for our customers. We are excited to offer this complimentary service alongside our rapid machining and sheet metal fabrication services to help our customers innovate faster.” -Roy Dietsch, CEO, Parts Badger

What is 3D Printing?

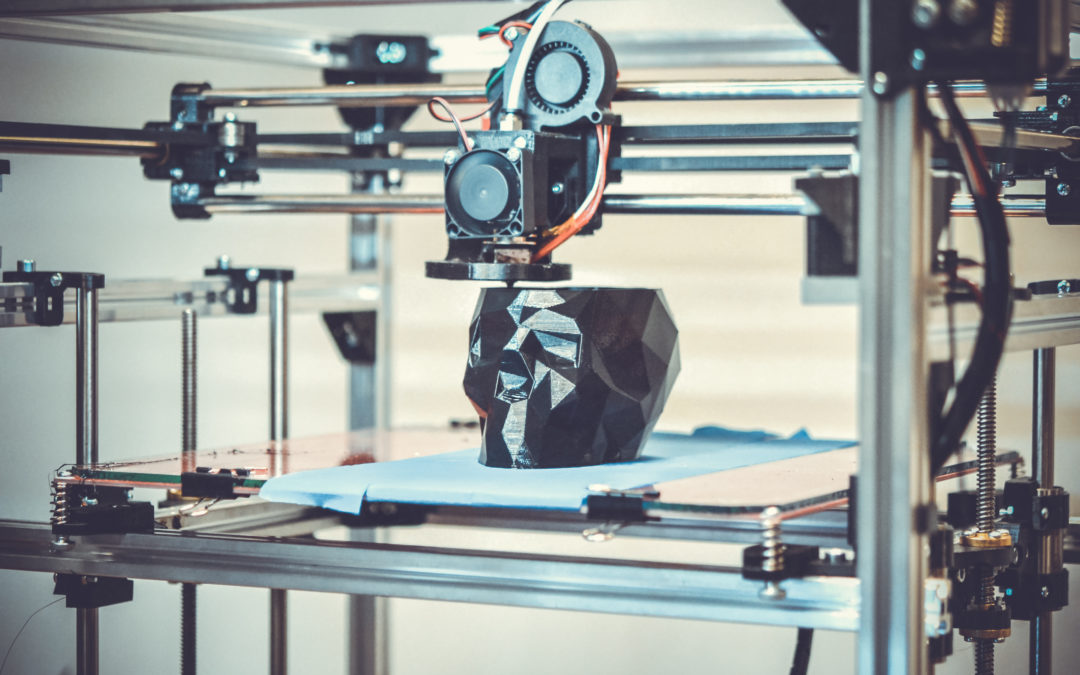

3D Printing is an additive manufacturing process, which is the complete opposite of a subtractive process. While subtractive manufacturing processes like laser cutting and metal bending take away from metal to create parts, additive manufacturing builds parts from a 2D model. Originally known as rapid prototyping, 3D printing is the process of building 3D solid objects from a digital file. During this process, thermoplastic prints from the bottom up with directions from G-Code to create the object. Typically, file types used are .STP, .STEP, .STL, .PDF, or .DWG.

3D Printing Capabilities

Parts Badger will offer a wide variety of 3D printing options. These include:

- Fused Filament Fabrication (FFF)

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- Digital Light Projection (DLP)

- Stereolithography (SLA)

Fused Filament Fabrication

Fused Filament Fabrication (FFF) allows for continuous fiber reinforcement to add on the interior of the part. Additional fiber reinforcement can be added to drastically increase strength and other properties of the part. This will create increased strength and reliability for each product. Materials that can be used include carbon fiber infused black nylon and white nylon. Post printing processes include support removal and internal threads.

Fused Deposition Modeling

Fused Deposition Modeling (FDM) precisely extrudes material from a nozzle layer-by-layer to form a part. It’s widely known for it’s print speed, visual impact, support, and competitive cost. FDM printers use filaments like thermoplastics to print the product from the base to the top.

Selective Laser Sintering

Selective Laser Sintering (SLS) uses a high-power laser to fuse small particles of plastic powder. The high accuracy and consistency of SLS makes it ideal for high quality production parts. Parts produced with SLS have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

Digital Light Projection

Digital Light Projection (DLP) technology uses a layer-less ultraviolet projector to cure photopolymer resin. It offers a higher resolution than other technologies, which allows you to print parts with fine details and surface finishes.

Stereolithography

Stereolithography (SLA) is a game changer for Parts Badger. SLA 3D printing machines are capable of printing extremely accurate parts using a wide range of resins. It’s great for fine details and parts that require injection mold like finishes. By offering Stereolithography, Parts Badger will make high quality products for all customers on an improved timeline. They can use a wide variety of materials to create the products that the customers ask for. These materials include standard resin, castable wax resin, rigid resin, tough resin, flexible resin, and high temp resin. Post printing processes also include support removal and internal threads.

This expansion is just one of many examples of how PartsBadger’s innovation led to being ranked #525 on Inc. Magazine’s Annual 5000 list in 2021. Other innovative ideas like instant quoting, 24/7 manufacturing, and adding sheet metal fabrication capabilities have led to a 936% three-year revenue growth and separation from the competition. By expanding to 3D Printing services, they will continue to innovate. Parts Badger continues to lead the charge to innovate the CNC industry.

Click here to request a quote for your next 3D Printing job.

We Are Your Online CNC Machine Shop

Parts Badger creates your exact designed product. We use Instant quoting and 24/7 manufacturing to get your products created and back to you very quickly. Our services include but are not limited to:

Our knowledgeable team of experts will work closely with you to create high-quality components fabricated to your unique specifications, regardless of complexity. Contact us or request your rapid quote today to work with us on your next project.

Recent Comments