Material Options

Instant Online Quote for Titanium Parts

Enter your dimensions, material, finish, and features your part needs and let our Instant Quote algorithm give you immediate pricing.

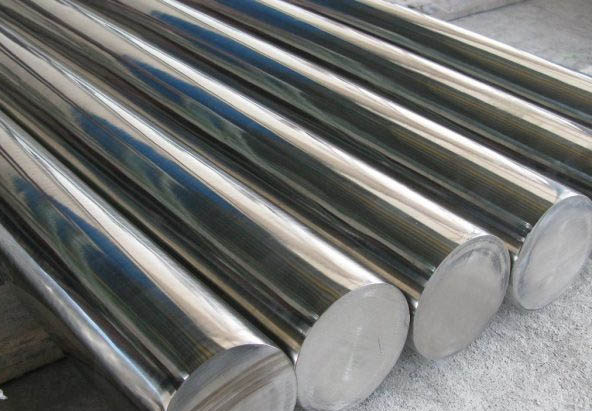

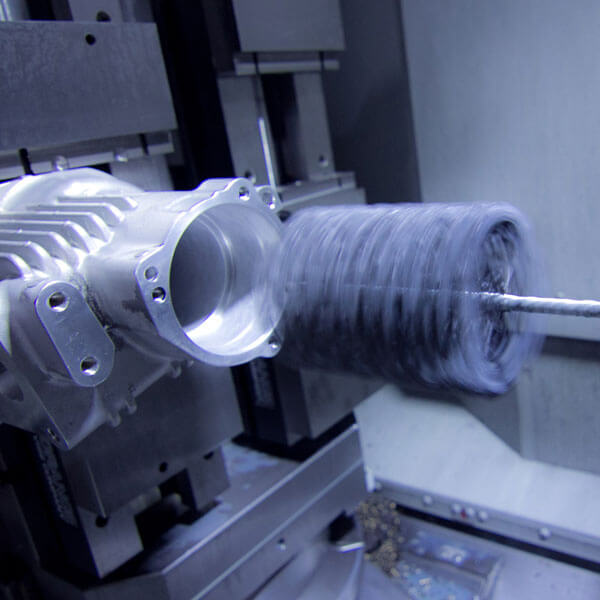

High Performance Alloys, Titanium & Exotics

Titanium and other High-Performance Alloys contain high corrosion resistance, high strength and rigidity, and the ability to withstand elevated temperatures, making them perfect for parts that need to hold up in the most extreme conditions. They are popular in aerospace applications and can be used for rotors, compressor blades, hydraulic components, engines, frames and much more.

Titanium is also biocompatible and not rejected by the body, making it a top choice for many medical applications like impants and surgical implements.

High Performance grades available for CNC Machining at PartsBadger:

Nickel Alloys

- Hastelloy X

- 400

- 405

- 500

- 600

- 601

- 625

- 718

- RA330®

- RA333®

- RA 602 CA®

- Alloy X

- INVAR 36

- AL-6XN®

- X-750

- 800H/AT

- Alloy 20

- 230®

- Alloy W

Copper Nickel

- C71500

Beryllium Copper Alloy

- C17200

Cobalt Alloys

- 188

- C263

- René 41

- TRIBALOY® T-800®

- WASPALOY®

- 694

- L605

Cobalt Chrome

- 1537

HY 80 / 100 STEELS

- HY 80

- HY 100

Naval Brass

- C46400

Titanium

- Titanium Grade 1

- Titanium Grade 1, Annealed

- Titanium Grade 2

- Titanium Grade 2, Annealed

- Titanium Grade 3

- Titanium Grade 3, Annealed

- Titanium Grade 4

- Titanium Grade 4, Annealed

- Titanium Grade 7

- Titanium Grade 7, Annealed

- Titanium Ti-15V-3Cr-3Al-3Sn Solution Treated

- Titanium Ti-15V-3Cr-3Al-3Sn ST 790°C, Aged 480°C

- Titanium Ti-15V-3Cr-3Al-3Sn ST 850°C (1560°F), Aged 545°C

- Titanium Ti-3Al-2.5V, alpha annealed

- Titanium Ti-3Al-2.5V, Alpha-Beta Anneal, Quenched

- Titanium Ti-3Al-2.5V, Beta-Anneal 950°C

- Titanium Ti-3Al-2.5V, ST 925°C, Aged 480°C

- Titanium Ti-5Al-2.5Sn

- Titanium Ti-5Al-2.5Sn, ELI, Annealed

- Titanium Ti-6Al-2Sn-4Zr-2Mo, Duplex Annealed

- Titanium Ti-6Al-2Sn-4Zr-2Mo, Sheet

- Titanium Ti-6Al-4V (Grade 5), Annealed

- Titanium Ti-6Al-4V (Grade 5), Annealed Bar

- Titanium Ti-6Al-4V (Grade 5), ELI, Annealed

- Titanium Ti-6Al-4V (Grade 5), STA

- Titanium Ti-6Al-4V (Grade 5), STA Bar

- Titanium Ti-6Al-6V-2Sn Annealed

- Titanium Ti-6Al-6V-2Sn STA 870°C/565°C

- Titanium Ti-6Al-6V-2Sn STA 910°C/540°C

- Titanium Ti-8Al-1Mo-1V

- Titanium Ti-8Al-1Mo-1V Annealed 8 hr at 790°C (1450°F)

- Titanium Ti-8Al-1Mo-1V Duplex Anneal

- Titanium Ti-8Al-1Mo-1V, Beta Annealed, Aged

- Titanium Ti-8Al-1Mo-1V, Beta Solution Treated

- Titanium Ti-8Al-1Mo-1V, ST 980°C (1800°F), Aged 595°C

Titanium Alloys

- Grade 1

- Grade 2

- Grade 2 Ae

- Grade 3

- Grade 4

- Grade 4 Ae

- Grade 7

- Grade 11

- Grade 17

- Grade 70

- 5Al-2.5SN

- 6Al-4V

- 6Al-4V ELI

- 6Al-4V-STA

- 6Al-2Sn-4Zr

- 6Al-2SN-4ZR-2MO

- 6Al-2SN-4ZR-6MO

- 6Al-6V-2SN

- 7Al-4Mo

- 8Al-1MO-1V

- CP

Aluminum Bronze

- C62300

- C63000

- C63200

- C64200

Phosphor Bronze

- 51000

Silicon Iron Bronze

Cast Bronze

- CDA 65500

- CDA 67500

- CDA 86400

- CDA 90300

High-Temperature Super Alloy

- Allegheny Ludlum Altemp® A286 Iron-Base Superalloy, UNS S66286

- Haynes® 188 alloy, 0% cold reduction, 3.2 mm thick sheet

- Haynes® 188 alloy, 10% cold reduction, 3.2 mm thick sheet

- Haynes® 188 alloy, 20% cold reduction, 3.2 mm thick sheet

- Haynes® 188 alloy, 30% cold reduction, 3.2 mm thick sheet

- Haynes® 188 alloy, 40% cold reduction, 3.2 mm thick sheet

- Haynes® 188 alloy, cold rolled

- Haynes® 188 alloy, hot rolled

- Haynes® 188 alloy, plate

- Haynes® Hastelloy® X alloy, sheet

- Haynes® Multimet® alloy, 1.32 mm thick sheet

- Haynes® Multimet® alloy, 1.6 mm thick sheet, 1177°C heat treatment, rapid air cooled, tested at 1093°C

- Haynes® Multimet® alloy, 12.7 mm (1/2 in.) thick plate

- Haynes® Multimet® alloy, 12.7-50.8 mm hot-rolled bar

- Haynes® Multimet® alloy, 25.4-50.8 mm forged bar

- Haynes® Multimet® alloy, 533.4 by 82.55 mm forging

- Haynes® Multimet® alloy, 533.4 by 82.55 mm forging

- Haynes® Multimet® alloy, 6.15 mm hot-rolled bar

- Nickelvac® A-286 Specialty Steel

- Nickelvac® L-605 Nickel Superalloy

- Rene 41® Nickel Superalloy

- Special Metals INCO® A-286 Iron-Nickel-Chromium Alloy

- Special Metals INCONEL® Alloy 600

- Special Metals INCONEL® Alloy 617

- Special Metals INCONEL® Alloy 625

- Special Metals INCONEL® Alloy 718

- Special Metals INCONEL® Alloy X-750

- Special Metals NIMONIC™ Alloy 901

- Waspaloy® Nickel Superalloy

& more available upon request

Available surface finishes for CNC machined parts:

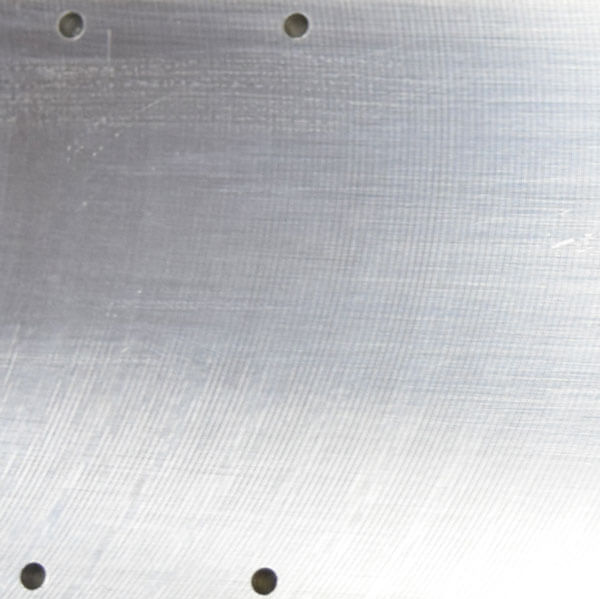

Deburr/Mill

Rough Polish

Bead Blast

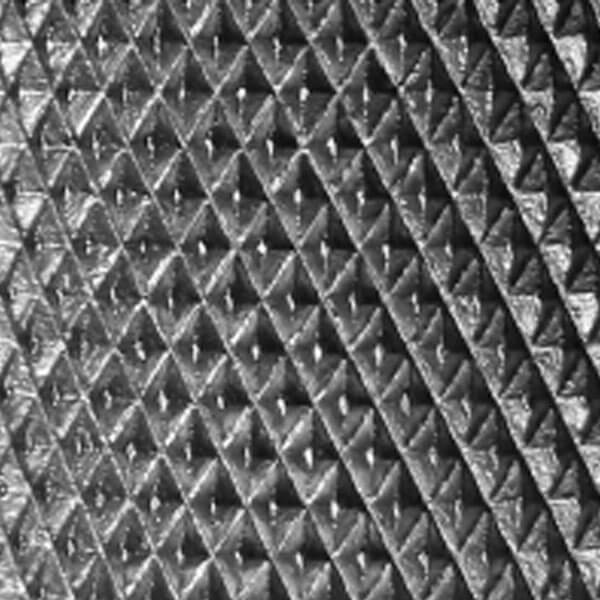

Knurling

Brushing

Tumbling

Surface treatments available for CNC machined parts:

Anodizing

Sulfuric Anodize MIL-A-8625/Type II Type II, Class 1 ; Type II, Class 2 Hard Anodize MIL-A-8625/Type III Type III, Class 1 ; Type III, Class 2 Anodizing creates a thin oxidized layer that may be dyed a certain color. Anodizing is only available on Aluminum or Stainless Steel materials. Anodizing will make the surface non-conductive. Type I thin or Type III thick anodizing is available. Colors include: Clear, Black, Red, Blue, Orange, Purple, Green, and Brown.

Chromate Conversion/Alodine

MIL-DTL-5541 ; Hexavalent Yellow and Trivalent Clear Type I, Class 1A ; Type I, Class 3 Type II, Class 1A ; Type II, Class 3 Chromate Coating provides additional corrosion resistance or as a primer for powder coating while maintaining conductivity. Chromate coatings are soft and gelatinous when first applied, but harden and become hydrophobic as they age. This process creates an iridescent or yellow tint to the part.

Electropolishing

ASTM-B-912 One of the benefits of electropolishing for stainless stee, is that it removes iron from the surface and enhances the chromium/nickel content. This process creates a mirror like finish on the part, creating a higher polish than what can be created manually. Surface quality obtained by Electropolishing is directly related to the quality of the pre-electropolished surface. Electropolishing cannot remove digs, gouges, scratches or other similar surface distortions.

Passivation

ASTM A967, AMS2700, ASTM A380 Passivation uses a nitric or citric acid to create a protective oxide layer on parts made from austenitic, ferritic, and martensitic corrosion-resistant steels. The protective layer helps improve the corrosion resistant qualities of the metals.

Nickel and Silver Electroplating

Electroplating adds a thin layer of metal onto another metal object. The plated layer can be decorative, provide corrosion resistance, wear resistance, or used to build up worn or undersized parts for salvage purposes.

Ceramic Coating

We offer various brands of ceramic coating. Cerakote (H-240) is a Polymer-Ceramic Composite ceramic coating that can be applied to metals, plastics, polymers and wood. The unique formulation used for Cerakote ceramic coating enhances a number of physical performance properties including abrasion/wear resistance, corrosion resistance, chemical resistance, impact strength, and hardness.