The PartsBadger Blog

Stay up to date with news and highlights about PartsBadger and our industry.

SLA vs DLP

One of the most popular 3D printing topics are the debate between SLA vs DLP 3D printers. Both use resins to form the objects and light to solidify the resin’s layers. The big difference between the two are the type of lights the 3D printers use.

SLA vs FDM

SLA vs FDM One of the most popular 3D printing topics are debating between SLA vs FDM. Hobbyists most commonly use FDM printers out of affordability, while CNC machinists use SLA out of quality and efficiency. To back it up, the 3D printer is a tool that creates rapid...

DLP 3D Printing Applications

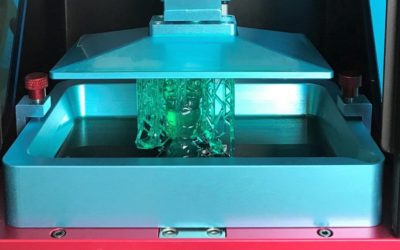

Unlike SLA, DLP only requires a shallow vat of resin to facilitate its process. Thus, it results in less waste on its materials. It also lowers its running costs. DLP also prints 3D parts significantly fast. This is because it allows for curing the whole surface of a layer all at once. With all of these aspects, DLP 3D printer applications are very popular in different industries.

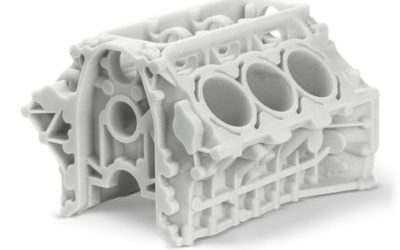

SLS 3D Printer Guide

What is an SLS 3D Printer? An SLS (Selective Laser Sintering) 3D printer is a tool that creates rapid prototypes through polymers. 3D Printing is an additive manufacturing process, which is the complete opposite of a subtractive process. While subtractive...

Parts Badger CEO Joins Panel Discussion on Entrepreneurship

Roy Dietsch Joins BizTimes’ Innovation + Entrepreneurship Forum & Awards Panel Discussion Roy Dietsch, co-founder and CEO of Parts Badger participated in a panel discussion with fellow entrepreneurs Kyle Weatherly, co-founder and CEO of Frontdesk and Jackie...

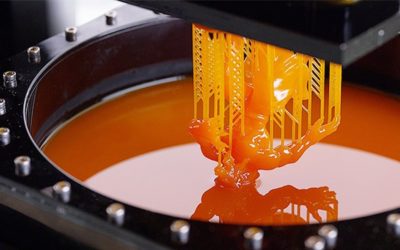

DLP 3D Printer Guide

A DLP 3D Printer is a tool that creates rapid prototypes through photopolymer resin. 3D Printing is an additive manufacturing process, which is the complete opposite of a subtractive process. While subtractive manufacturing processes like laser cutting and metal bending take away from metal to create parts, additive manufacturing builds parts from a 2D model. Unlike Stereolithography (SLA) printing, which uses a laser to create 3D objects, DLP uses a light projector instead.

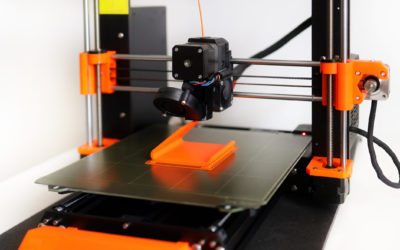

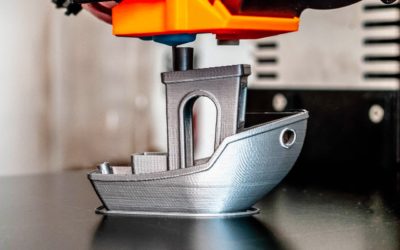

FFF 3D Printer Guide

What is an FFF 3D Printer? An FFF (Fused Filament Fabrication) 3D printer is a tool that creates rapid prototypes through filaments. 3D printing is an additive manufacturing process, which is the complete opposite of a subtractive process. While subtractive...

PartsBadgers Hires Marketing Coordinator

Parts Badger hires a new marketing coordinator in December to expand the marketing team. Jeremy Hansen will take charge of content creation, social media, landing page creation, and SEO management on the website.

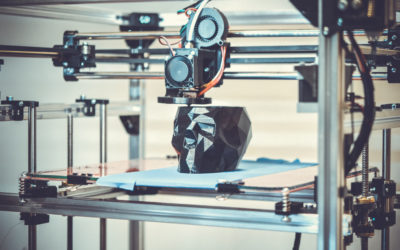

SLA 3D Printer Guide

An SLA 3D Printer is a tool that creates rapid prototypes through photopolymer resin. 3D Printing is an additive manufacturing process, which is the complete opposite of a subtractive process. Unlike Fused Depositional Modeling printing, which uses filaments to create 3D objects, SLA uses resin instead.

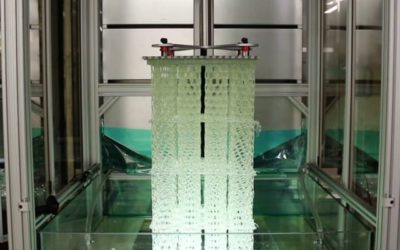

Parts Badger Expands 3D Printing Capabilities

Parts Badger is now offering 3D Printing services to all their customers. After receiving many inquiries about the service, Roy Dietsch, CEO of PartsBadger, made the decision to expand their capabilities to 3D printing.

Recent Comments