A DLP (Digital Light Projection) 3D printer is a tool that creates rapid prototypes through photopolymer resin. Unlike SLA 3D printers, which uses a laser to create 3D objects, DLP 3D printers use a light projector instead. When comparing to other 3D printers, DLP 3D printers have an excellent resolution. The resolution makes this printer very popular by creating incredibly accurate parts.

Unlike SLA, DLP only requires a shallow vat of resin to facilitate its process. Thus, it results in less waste on its materials. It also lowers its running costs. DLP also prints 3D parts significantly fast. This is because it allows for curing the whole surface of a layer all at once. With all of these aspects, DLP 3D printer applications are very popular in different industries.

DLP 3D Printing Applications

With the high accuracy, you can imagine all of the applications this 3D printer is used for. Here are the main industries that resin models are of particular use for:

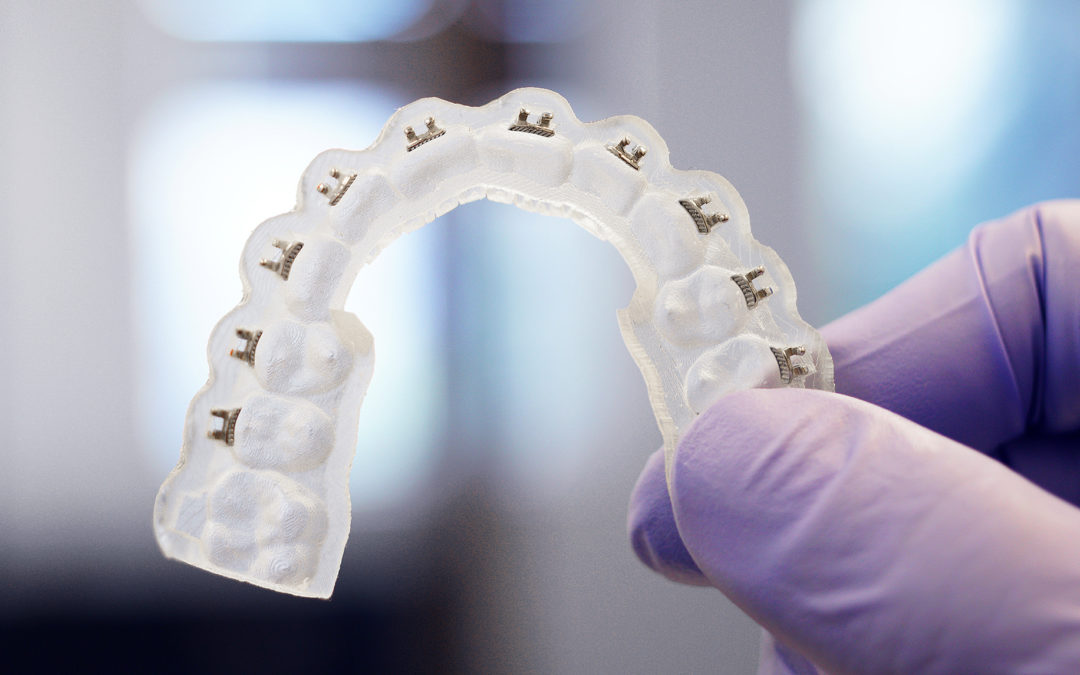

Dentistry Applications

The first DLP 3D printing application is dentistry. The dentists must create molds that are the exact shape of the patient’s teeth. This requires accuracy that only the DLP 3D printer can create. DLP is able to make dentistry models that include orthodontics, teeth molds, The first is in dentistry, which includes making models for use in orthodontics, teeth molds, and more.

3D printing, in general, is the perfect way to create these molds. By dentists using the additive manufacturing process, they build the objects from nothing. 3D printing is the process of building 3D solid objects from a digital file. G-code is the most common file format. This file contains coordinates to guide the printer’s movements to print the material. These coordinates guide the printer’s movements, both horizontally and vertically, through the x, y, and z axes. 3D printer resolution separates into two different segments: Z resolution (vertical) and XY resolution (horizontal).

Dentists use surgical guide resin to create the molds. Surgical Guide Resin is an autoclavable, biocompatible resin for applications including 3D printing dental surgical guides for implant placement.

By using resin, this benefits the user even more. Resin permanently hardens after being heated and cooled. This makes sure that the molds don’t change shape while in the patient’s mouth.

Jewelry Pieces

The second DLP 3D printer application is in jewelry in making molds to create solid metal jewelry pieces. DLP’s ability to create detailed and intricate pieces is invaluable in this process. As customers are looking for the next complex look, the natural way of making jewelry pieces is becoming too time consuming.

By using DLP 3D printers, the jewelers have a much easier time creating these designs. DLP makes jewelry much quicker than the old way. This means less labor is needed on these projects. With a more simpler way of creating jewelry, businesses can mass produce the jewelry at a lower cost.

Jewelers use castable resin to create this jewelry. This resin is an acrylate photopolymer, which requires a different process from a traditional wax schedule. According to Zortrax, high quality castable resins have physical properties nearly identical to wax, so they can be processed with the same set of tools and used with the same investments.

Hearing Aids

Lastly, DLP can create hearing aids. Hearings aids are one area where, despite its infancy, 3D printing has utterly taken over. DLP and SLA 3D printing make 98% of hearing aids . This is because people’s ears vary in shape and size and a custom sized hearing aid needs to be made for each patient, making 3D printing the most effective production method.

Polyurethane-based resins present an ideal solution to high demands of hearing aids. According to resin-expert.com, polyurethanes are synthetic resins or plastics that result from a polyaddition reaction between dialcohols or polyols and polyisocyanates. It has a very high heat resistance after curing. This means that it can withstand the highest temperatures.

If you are in need of a service for similar 3D printer applications, you should consider Parts Badger. Our DLP 3D printing service will get your parts printed in break-neck speed. Click here to request a quote for your next 3D printing job.

We Are Your Custom CNC Machine Shop

Parts Badger creates your exact designed product. We use Instant quoting and 24/7 manufacturing to get your products created and back to you very quickly. Our services include but are not limited to:

Our knowledgeable team of experts will work closely with you to create high-quality components fabricated to your unique specifications, regardless of complexity. Contact us or request your rapid quote today to work with us on your next project.

Recent Comments