What is a prototype?

A prototype is an initial version of a product that allows you to explore your ideas and show the intention behind a feature or the overall design concept before investing time and money into full development. A prototype can be anything from a 3d printed piece to a rough, low-fidelity, CNC machined version.

Fidelity of a Prototype

The fidelity of a prototype refers to its level of completeness and detail. The degree of completeness of the prototypes you build depends on the stage of progress; these include the following:

- Low fidelity – low cost, rough and quick to build

- Medium fidelity – slightly more detailed, still rough but closer to the solution

- High fidelity – much closer to final, very detailed and much more time-consuming

This represents a scale of completeness or closeness to the final product, which differs depending on the type of solutions and needs of the situation. Prototypes can also have different parts with varying levels of fidelity. For example, you can build a prototype with high visual fidelity but with low functional fidelity — which would be useful if you were testing the visual aspects, rather than functional aspects of the prototype. The main aspects, which are the focus of the prototype, should receive more focus and, ideally, higher fidelity.

CNC Machining vs 3D Printing: Which is Better for Your Prototyping Process?

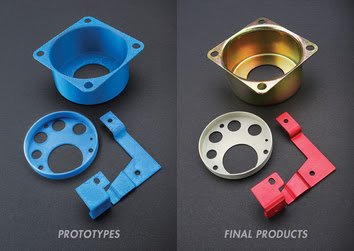

The most obvious difference between these two manufacturing technologies is that 3D printing is much cheaper and is capable of building geometries that are impossible or impractical to machine, such as curved deep holes, interior square corners or fully enclosed hollow sections. CNC machining, on the other hand, offers speed and accuracy.

For initial, low-fidelity prototypes 3D printing is a popular choice. WIth the cost of entry for a 3D printer being a fraction of the cost of a CNC machine, product developers can save a lot of time and money by 3D printing their non-functional iterations on a 3D printer.

A major point to consider when designing and 3D printing prototypes, is that sometimes the geometries and features that can be 3D printed do not translate well when it comes time to CNC machine the part.