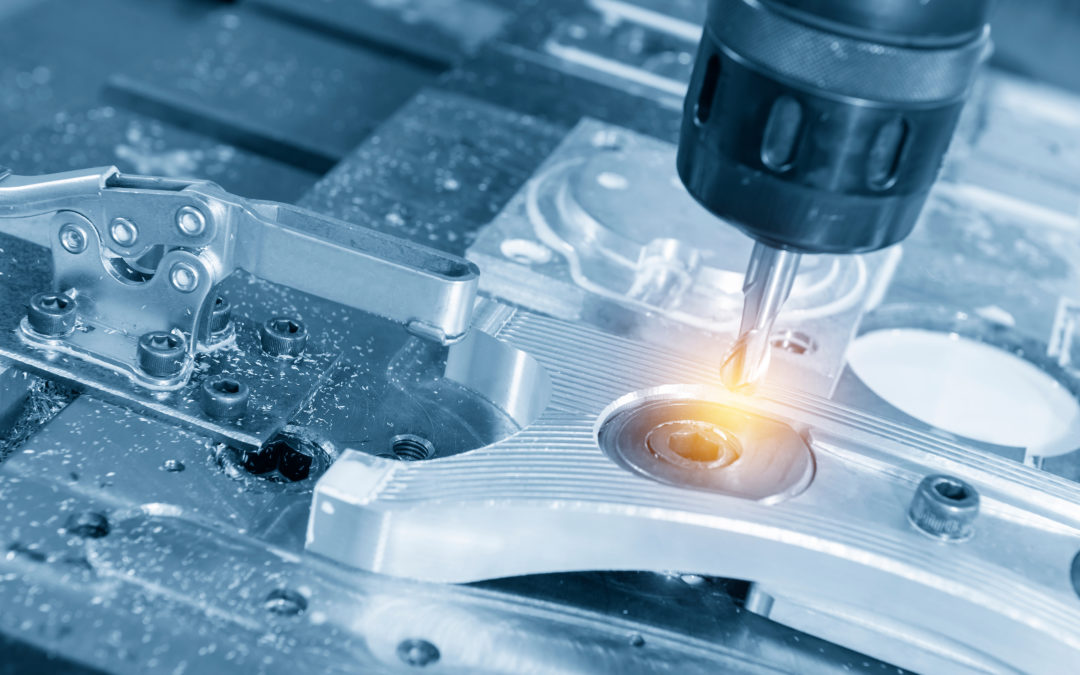

What is the Difference Between Drilling and Tapping?

Drilling and tapping are both processes that involve using specific cutting tools to remove metal from an object in order to create either a threaded hole or simply a smooth hole in the object’s surface. However, while they may seem similar at first glance, drilling and tapping actually serve very different purposes, as well as requiring very different types of tools and processes in order to be done successfully. Let’s take a look at how these two processes differ, what they’re used for, and why one might be more suitable than the other in certain circumstances.

What are Drilling and Tapping

Drilling and Tapping are both processes which are used to create holes in metal parts. While it can sometimes be hard to differentiate between them, there is a slight but important difference. Drilling involves using a tool known as a drill bit (or end mill) which rotates on its axis while being pushed through a predrilled hole in order to create a new hole. Tapping, on the other hand, uses an external cutting device that threads itself into pre-existing threads in order to cut them further.

They are often used in combination with each other when working with metals. For example, if you want to create a screw hole which extends deeper than 1 thread then you will use a tap drill.

How do they relate to each other

Both drilling and tapping are common ways to cut internal holes in metal, plastics, wood, or other materials. The main difference lies in how you measure a hole before cutting it into your material.

When tapping a hole, you’re using an off-the-shelf tap (most commonly with a 1/4 or 3/8 thread) to cut threads into your material.

When drilling a hole, you’re creating an internal hole by forcing a drill bit through your material. A tap follows preexisting threads on a bolt or screw, whereas a drill doesn’t have any predefined route to follow. It cuts as it goes along.

Both tapping and drilling require a specific tap or drill bit to be used in order to avoid damage to your material.

There are many ways to cut internal holes in a material. However, tapping and drilling are two of the most common – especially for smaller-sized holes.

Advantages of Drilling/Tap over Using Threaded Components

Drilling a hole allows you to be extremely precise with what goes into it. And by using tap drill, you can eliminate cross-threading when attempting to put something in a thread.

A tap drill has a higher tolerance for error than does tapping, which means that you don’t have to be as careful. Because of that, a tap drill can go faster than tapping.

With a tap drill, you don’t need to use lubricant. Lubricant can get into your threads, sometimes making them useless in some applications. Tap drills can also be used for milling operations. Drilling alone cannot be used for such an operation.

Drilling vs. Tapping

When it comes to metalwork, there are a number of terms that can be very confusing. However, there are 2 terms that you should know about: tapping and drilling. Both have their uses.

The main difference between tapping and drilling is that tapping uses a smaller drill bit than when you are drilling. This leaves a gap on the underside of whatever you’re tapping. When you’re tapping, you want to drill all of the way through.

Both tapping and drilling can be used to join 2 pieces of metal together. But they are different ways of doing it! That’s why it’s good to understand them both!

Why Drill/Tap Might be Preferred

Convenience, simplicity, durability. The decision to drill/tap a hole rather than use a press-fit or other method depends on several factors: the geometry of how (and where) two pieces will join together, plus whether they’ll need to be separated in service. For instance, if you plan to install screws that serve as a mechanical fastener while also providing electrical continuity (using both conductive metal as well as nonconductive plastic), then drilling/tapping may be your best option.

In applications where electrical conductivity isn’t important, a nonconductive material such as plastic or glass may be used. Drill/tap applications are also found in mechanical fasteners, where things can get complicated.

About PartsBadger

From prototyping to manufacturing, let PartsBadger take care of your manufacturing needs. We’re here to help answer any questions you might have about our manufacturing techniques to get your custom parts made.

PartsBadger has state-of-the-art equipment like computer numerical control (CNC) mills, CNC lathes, laser cutters, water jet machines, die cast machines, sheet metal bending machines, 3D Printing, and more. This is the company that will give you the exact custom parts you need.

Contact us today for your quote or to find out more about our services.

Recent Comments