Discover How CNC Milling Transforms Modern Production Processes

What Are the Three Key Facts You Need to Know About CNC Mills?

CNC mills offer unparalleled precision, material versatility, and a promising future with increased automation and sustainability. They provide tight tolerances and consistent quality across diverse materials, making them indispensable in industries like aerospace and automotive.

- Introduction to CNC Mill Technology

- The Precision of CNC Mill

- Material Versatility with CNC Mill

- Future of CNC Mill in Manufacturing

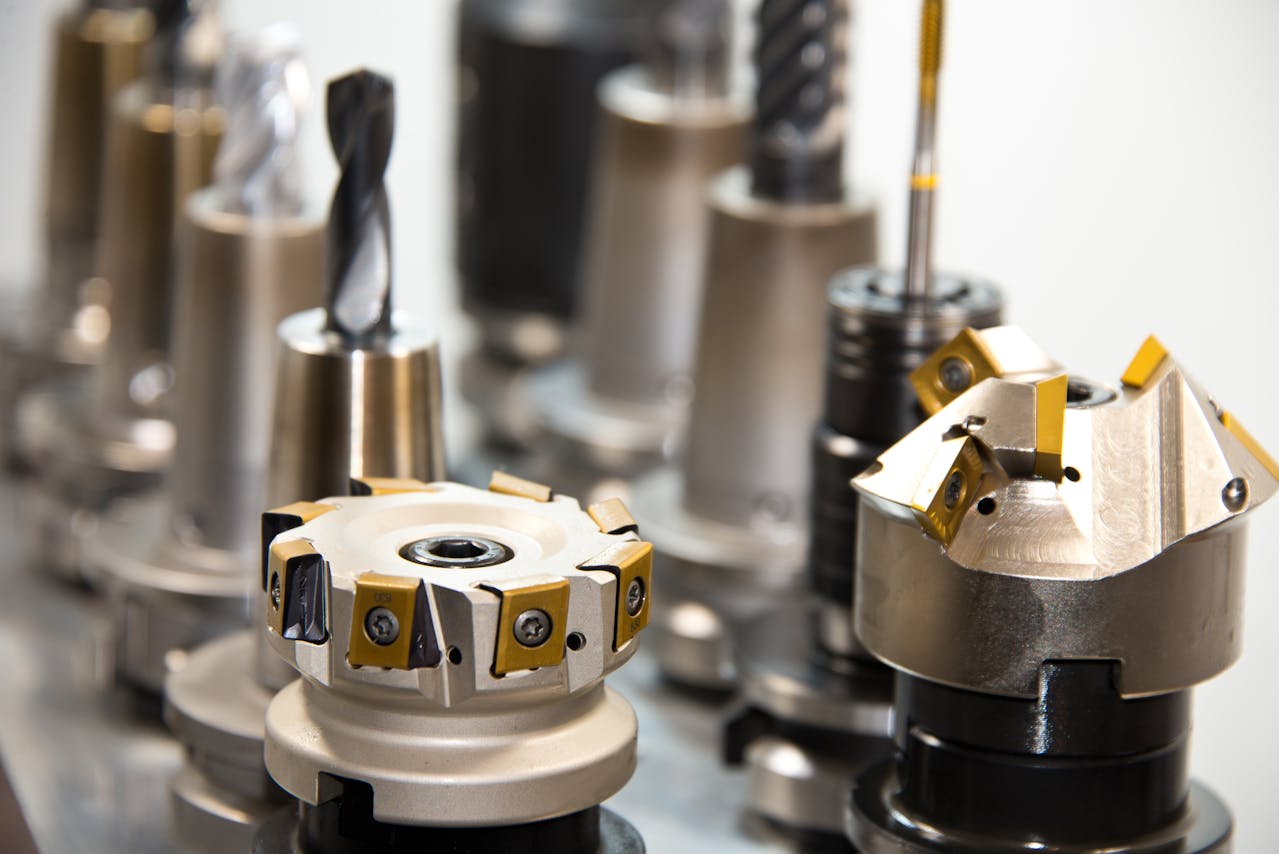

Introduction to CNC Mill Technology

CNC mill technology is a game-changer in modern manufacturing. This method uses computer-controlled machines to carve, cut, and shape materials with astonishing accuracy. Here’s what makes it so special:

- Precision at Its Best: Every CNC mill works with precision that traditional methods can’t match. It’s like having a super-accurate sculptor who never gets tired or makes a mistake.

- Material Maestro: From metals to plastics, CNC mills can handle just about anything. This versatility makes them a go-to choice for a wide range of industries.

- Looking Ahead: The future of CNC milling is bright, with advancements in technology continuously enhancing its capabilities.

As one expert puts it, “CNC milling is not just a process; it’s a vital tool in modern production that keeps getting better.” This technology not only meets the high standards of today’s markets but also pushes the boundaries of what’s possible in manufacturing. The journey of a CNC mill in transforming materials into precise parts is nothing short of remarkable. It’s a core part of industries from automotive to aerospace, making it a cornerstone of industrial innovation.

The Precision of CNC Mill

When it comes to the magic of manufacturing, CNC mills are often at the center of the conversation. Why? Because they transform big ideas into precise physical objects with an accuracy that seems almost too good to be true.

- Unmatched Precision: CNC mills operate with a level of precision that manual processes can’t match. Imagine cutting a piece of paper into a complex shape using just scissors. Now think about doing that with metal or plastic — that’s where CNC mills shine. They can produce parts with tolerances as tight as a few micrometers, ensuring every piece is exactly the same.

- Consistent Quality: No more worries about human error. CNC mills follow exact instructions from computer programs, making each cut with the same precision every time. This consistency is crucial for industries where every micrometer counts, like in aerospace or medical devices.

“You can expect perfection every single time with CNC mills,” says a seasoned engineer from the field. This quote highlights the reliability and repeatability that make CNC mills an invaluable tool in modern manufacturing.

Looking ahead, the future of CNC milling promises even greater accuracy as technology advances. This means tighter tolerances, less waste, and more possibilities for innovation in various fields. It’s not just about making things; it’s about making things perfect.

Material Versatility with CNC Mill

When it comes to versatility, CNC mills are in a league of their own. These powerful machines can handle a vast array of materials, ensuring that no matter your project, a CNC mill has got your back.

- Wide Range of Materials: From soft plastics to tough metals like titanium, CNC mills can cut through nearly anything. This makes them perfect for a variety of industries, from jewelry making to aerospace engineering.

- Adaptable for Any Project: Whether you’re creating a delicate piece of art or robust mechanical parts, CNC mills adapt to the complexity and intricacies of your designs.

As one expert puts it, “CNC mills are like the Swiss Army knife of the manufacturing world; they can tackle just about anything you throw at them.” This adaptability not only streamlines production but also opens up infinite creative possibilities. Looking ahead, the horizon for CNC mills in manufacturing looks bright, with ongoing advancements pushing the boundaries of what these machines can achieve.

Future of CNC Mill in Manufacturing

The future of CNC mill technology in the manufacturing world looks brighter than ever! As we dive into what’s next, here are some exciting trends to keep an eye on:

- Automation and Integration: CNC mills are becoming more integrated with other manufacturing processes. This means smoother workflows and even faster production times.

- Advancements in Technology: With each passing year, CNC mills are getting smarter. They’re incorporating artificial intelligence (AI) and machine learning to enhance precision and efficiency.

- Sustainability Focus: Manufacturers are increasingly using CNC mills to create products with less waste. This not only helps the planet but also cuts down costs, making sustainable practices a win-win.

As one industry expert puts it, “The potential for CNC mills in the future of manufacturing is limitless. They are set to revolutionize the industry by improving speed, efficiency, and sustainability.” This forward-thinking approach is what keeps CNC mill technology at the forefront of innovation.

With these advancements, CNC mills are not just tools of today—they’re shaping the future of how we create and produce. It’s an exciting time to watch this space!

At PartsBadger, we are deeply committed to enhancing the precision and efficiency of your manufacturing processes through our state-of-the-art CNC mill capabilities. Our innovative approach allows us to deliver high-quality parts at an accelerated pace, ensuring you stay ahead in competitive markets. By integrating the latest technologies and advanced techniques in CNC milling, PartsBadger not only meets but exceeds the expectations of industries demanding meticulousness and reliability. Whether you’re involved in aerospace, automotive, or any sector requiring complex components, our expertise in CNC milling is your gateway to achieving higher performance and cost-effectiveness. Our dedicated team of professionals uses their deep knowledge and experience to provide tailored solutions that directly address your unique challenges and pain points. Let PartsBadger be your trusted partner in navigating the intricacies of modern manufacturing. Choose us for our commitment to innovation, precision, and your success. Explore our cnc mill services today and experience how we’re redefining industry standards with every project we undertake. Our mission is clear: to provide you with superior CNC milling solutions that propel your projects to the next level.