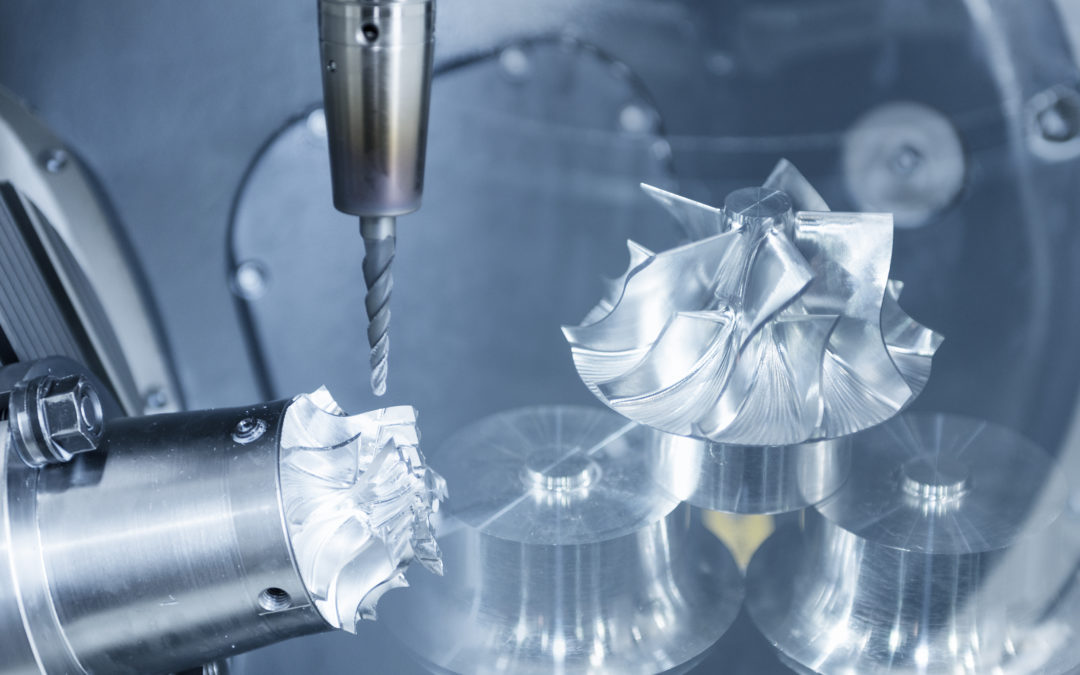

What is 5 Axis Milling?

When it comes to machine tools, five-axis milling refers to milling machines that have the ability to machine in three dimensions and can also rotate on their own axis. A typical five-axis milling machine allows you to mill complicated shapes with ease and is equipped with 5 axes of movement. These 5 axis include 3 rotary axis (X, Y, Z) and 2 linear axis (A, B). The three rotary axes allow you to rotate the workpiece while the two linear axis allow you to move the workpiece along.

Why 5 Axis Milling Machines are needed

When most of us think about a 3-axis or a 4-axis machine, we refer to a machine that has an x-, y-, and z-axis. This allows it to move in 3 dimensions, which is called 3D milling. 5 axis milling has an additional rotary axis for such tasks as thread cutting. The final axis refers to as a tool change axis, because it allows for the user to use different tools without moving anything but that last motion.

On top of all that, there’s still one more axis. On any CNC machine with multiple axes, you can rotate your part at any angle relative to any plane. This includes even if it doesn’t line up with any axis. This is called quill rotation.

That’s where 5-axis machines come in. They have five axes instead of three or four. This gives them a huge amount of flexibility for creating intricate shapes with small clearances. These are parts that you couldn’t make on a 3- or 4-axis machine. The parts are also prohibitively expensive if you have to create them via conventional machining methods.

5 Axis Benefits

5 Axis machining allows for a higher degree of accuracy than conventional machines. Five-axis machining also has faster cycle times and less material waste than two- and three-axis machining.

Because five-axis machining enables a higher degree of accuracy than conventional machines, it is frequently used for parts that need to be highly precise. 5 Axis machining can create smooth surfaces and high-quality finishes on a part.

Five-axis machining is particularly effective when machining large and/or complex parts. While conventional machines require multiple setups to machine different sides of a part, five-axis machining allows operators to use a single setup.

How does 5 Axis Milling Machine work?

Milling machines are a staple in every manufacturing facility, but did you know that there is more than one type of milling machine? While CNC mills are one option, 5 Axis Milling Machines are another.

The name 5 Axis Milling Machine can be a bit misleading, because there are more axes involved than just five. While CNC mills have three axes that control their movement and one spindle axis, 5 Axis Milling Machines have four spindle axes and two turret-axis types.

The functions of the 5th Axis

The fourth and fifth axes offer more efficient ways to achieve 3D machining. The fourth axis allows you to move a cutter around a fixed point on an object.

The fifth axis goes a step further, allowing you to rotate an object around its own fixed point. This results in a more versatile, better-quality product.

The costs of 5 Axis Milling Machines

The cost of a 5 Axis Milling Machine varies from $10,000 – $100,000. The price of a miller will typically depend on how many axes are being controlled and what kind of machine you’re using.

PartsBadger will get your custom parts completed at a complete discount compared to this. Click here to learn more about PartsBadger.

About PartsBadger

From prototyping to manufacturing, let PartsBadger take care of your manufacturing needs.

We’re here to help answer any questions you might have about our manufacturing techniques to get your custom parts made.

PartsBadger has state-of-the-art equipment like computer numerical control (CNC) mills, CNC lathes, laser cutters, water jet machines, die cast machines, sheet metal bending machines, 3D Printing, and more. This is the company that will give you the exact custom parts you need.

Contact us today for your quote or to find out more about our services.

Recent Comments