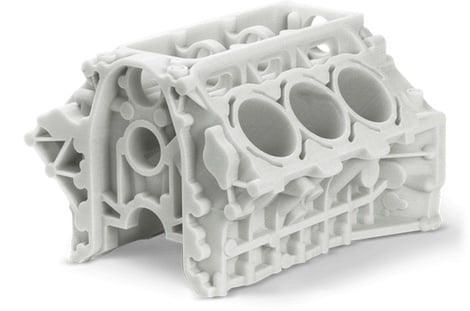

SLS (Selective Laser Sintering) 3D Printing

We utilize our SLS 3D printer service that is capable of fusing plastic powder together to create a 3D object. The printer preheats the powder to a temperature somewhat below the melting point of the raw material, which makes it easier for the laser to raise the temperature of specific regions of the powder bed as it traces the model to solidify a part from above.

SLS 3D printers have the highest resolution and accuracy, the sharpest details, and the smoothest surface finishes of all 3D printing technologies. Unlike thermosets, thermoplastics do not permanently mold after heating.

Size Specifications

6.5” x 6.5” x 12.6” (165 x 165 x 320 mm)

File Types

.STP, .STEP, .STL 2D drawing file also required

Tolerances

± 0.0197” (± 0.5 mm)

Material

Our current material options for our SLS 3D printing service include:

- Nylon 12

Post-Processing

Once the object completely prints, it must go through a post-processing. Processes can vary depending on the project. The SLS 3D printer requires much less than SLA printers. As the unfused powder supports the part during printing, there’s no need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

The machinist should remove, separate, and clean excess powder on the finished parts from the build chamber. Then they can use media blasting and media tumbling to further post-process the parts.

Parts that go through post-processing need to wait for the chamber to cool down. If it takes 24 hours to create a part, expect the chamber to wait 10 hours before removing from chamber. Once removal of object is complete, the machinist must collect excess powder for future projects via the media blaster, a vacuum-based recovery unit.

Vibratory polishing, also known as media tumbling, smooths the surface of SLS 3D printed parts by placing them in a vibratory tumbler. This extra step produces a satin-like surface finish, that allows parts to achieve smoothness that are typically impossible with media blasting alone. The result of media tumbling is a smoothness that gets rid of the rough exterior of the sintered nylon parts. Parts that use vibratory polishing are more scratch and dirt resistant than those that are not.

Lead Time

We strive to complete your parts at break-neck speed to keep your supply chain in order and get to market.

PartsBadger believes ordering custom parts ought to be simple, fast, and straightforward. We know that getting a price on your part without having to wait allows you to move faster, which means your ideas move forward. Let PartsBadger become a part of your supply chain as Your Online CNC Machine Shop.

Quick Quotes

Competitive Prices

No Minimums

Accelerate Your Innovation

We’re here to help you manufacture your machined parts efficiently and timely. We understand the importance of getting your product(s) to market before your competitors do. We provide quotes in hours and most parts in 14-Days or less. Use the form to reach our specialists to request a quote, check on an order status, or to learn more about us and our capabilities. We’re ready to accelerate your innovation.

Information

At PartsBadger, not all of the services we offer relate to a order. We know there is a lot of information out there and a lot of it is helpful. It is part of our mission to make sure the most helpful information is available to our customers. This is why we have compiled the key information about the CNC process, materials, and finishes.

Not sure what material you need? Or maybe you’re not sure what part category your project would fall into? We want to offer the information that will make your project right. So if you do run in to a issue or a question feel free to contact us.

Precision, Quality and Affordability at any volume

In addition to Urethane Casting, our Modern CNC machines can handle small radius cuts and maintain a high quality level whether you want one piece or one hundred. Chamfered edges, multi radius curves, and tapped holes are a few things that make machining a part more workable for any projects. We take pride in making quality, custom, low cost, cast and machined parts.