Designing Complex Parts? Here’s When Swiss CNC Machining Is the Smarter Choice

When it comes to outsourcing the production of high-precision parts, choosing the right machining process isn’t just a technical decision—it’s a strategic one. Whether you’re an engineer perfecting a complex design or a sourcing manager tasked with keeping production on track, understanding the capabilities of Swiss CNC Machining versus traditional CNC methods can lead to better outcomes in cost, performance, and reliability.

If your design includes tight tolerances, intricate features, or long, slender geometries—especially for smaller parts (think the size of a pen or smaller)—Swiss CNC Machining may be the smarter choice. Here’s why.

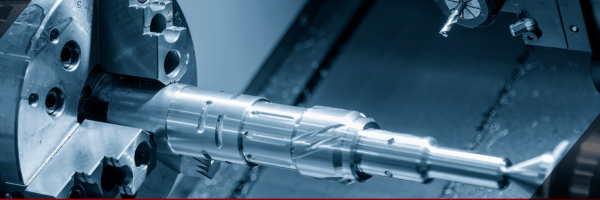

Swiss CNC Machining: Precision Born from Complexity

Originally developed for the Swiss watch industry, Swiss CNC Machining has evolved into the gold standard for producing small, complex components with exceptional accuracy. Unlike traditional CNC machines, Swiss machines move the material itself through a stationary cutting tool, allowing for superior support and ultra-precise cuts.

Why it matters: That added support minimizes deflection, making Swiss machining ideal for tight-tolerance, high-complexity parts that can’t afford even the slightest deviation.

Ideal Projects for Swiss CNC Machining

Swiss CNC machining shines in industries where precision is non-negotiable:

- Medical: Surgical tools, implants, and components with micro features

- Aerospace: Pins, spacers, and high-performance fasteners

- Electronics: Connectors, sensor housings, and miniature enclosures

- Defense & Automotive: High-stress, precision-fit components

And if you’re moving from prototype into production, Swiss machining can offer a seamless transition. (PartsBadger can help with the prototyping phase, too!)

Faster Production with Less Risk

Because Swiss machines are designed for continuous, lights-out production, they excel at turning out high volumes of precision parts with incredible consistency. They also reduce the need for secondary operations, tool changes, and manual intervention—meaning fewer delays, less waste, and more predictable costs.

Translation for sourcing teams: Swiss CNC machining can help you hit deadlines without compromising on quality.

Not Sure If Swiss CNC Is Right? That’s Okay.

Even if you’re not sure which machining process is best for your part—that’s okay! PartsBadger has the expertise and a wide range of machining capabilities. We’ll select the right process based on your design, timeline, budget, and production requirements.

Let’s Find the Right Fit for Your Project

At PartsBadger, we offer many different machining solutions. That means you don’t have to guess—we’ll guide you to the best approach based on your needs.

Ready to take the next step?

Submit your project in our portal or connect with our engineers to get expert insight on your next job.

Recent Comments