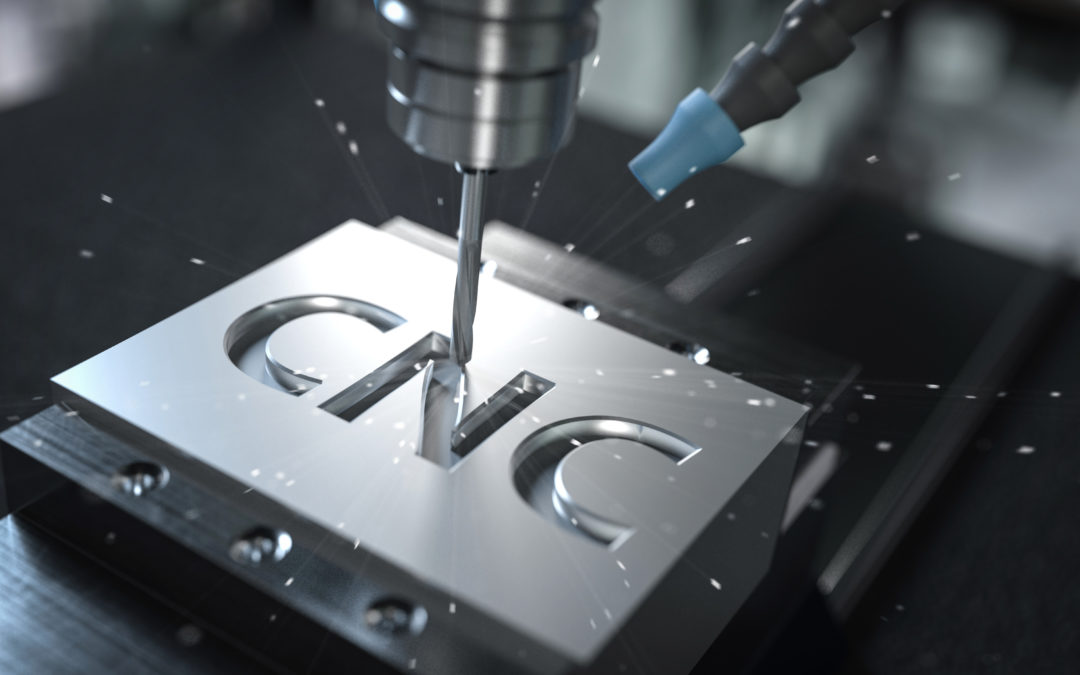

3D milling machines, also known as CNC machining centers, that use computers to control the creation of complex parts from raw materials. These machines can perform advanced functions like contouring surfaces and drilling holes with extreme precision. This makes them indispensable tools in the manufacturing industry.

They can create prototypes and reproduce specific parts of an object on a mass scale. In this article, we’ll explore the basics of 3D milling.

What is 3D CNC Milling?

Typically, CNC machines require 3 axis to accurately replicate an object. However, recent developments in software and machinery enable machines with 2 axis (2D) and even 1 axis (1D) to be effective CNC milling machines. This guide will cover the three types of 3D milling machines.

CNC milling is a subtractive process that removes material from a block to create an object. According to all3dp.com, subtractive manufacturing or subtractive fabrication involves cutting away from a solid block of material.

Essentially, it’s 3-dimensional carving. Machinists use computer programs called CAMs (Computer Aided Manufacturing). CAM communicates to a CNC machine where to mill and at what depth.

Generally, 2-axis and 1-axis machines can only mill in 2 or 1 dimensions. While 3-axis machines can mill in all three dimensions. they’re often more expensive than 2- and 1-axis counterparts. Additionally, most CNC machines are computerized. If you want to use a manual machine, you must find one that converts to CNC technology. There are not many that can do this though.

This is why it is best to work with PartsBadger to create your custom parts with our milling machines. Contact us to learn more about our services.

How does the 3D compare to traditional machining?

Three dimensional milling machines offer a number of advantages over traditional machining methods that make them perfect for certain applications. They are especially good at creating complex objects that other machines can’t make in any other way. This machine is also useful where the user needs to produce multiple copies of an object quickly and with high precision.

The machines work by using powerful rotating heads that can fit with a range of attachments and cutting tools. They use X, Y and Z axes to move around in three dimensions, enabling it to create any object from any angle.

A CNC milling machine uses computer-guided tools to cut through a wide range of materials.

5 ways in which 3D Milling are Different from Laser Cutting Machines

3D milling machines work on a different set of principles than laser cutting machines, which in turn result in them having different abilities. Here’s 5 ways in which 3D milling are different from laser cutting.

- Diameter-The smaller diameter of a laser cutter means that it can cut only smaller pieces, compared to those created with a 3D milling machine.

- Speed- Laser cutting machines are slower than 3D milling machines. Laser cutting machines can only work on one material at a time, while milling machines can handle multiple materials. Production cost is higher for laser cutting than for 3D milling.

- Durability– After 5 years of wear and tear, laser cutting machines need to be serviced or replaced, unlike CNC milling machines which can last for decades.

- Dependence– The positioning accuracy of a laser cutter is limited by its software whereas in a CNC milling machine it’s simply dependent on its accuracy and precision.

- Number of Axes– Laser cutting machines cut using only one axis, but a CNC milling machine has multiple axes which makes it possible to create deeper cuts.

3D Milling Advantages

3D milling machines offer a range of advantages over traditional 2D milling. These include:

- Increased surface finish

- Larger work envelope

- More accurate form

- Faster than CNC machining while also offering better accuracy than 2D drilling.

The 3D milling process works by moving a mill bit through its material while simultaneously rotating both in X, Y and Z directions. This allows for complex geometries to be cut away from a larger bulk material.

About PartsBadger

From prototyping to manufacturing, let PartsBadger take care of your manufacturing needs.

We’re here to help answer any questions you might have about our manufacturing techniques to get your custom parts made.

PartsBadger has state-of-the-art equipment like computer numerical control (CNC) mills, CNC lathes, laser cutters, water jet machines, die cast machines, sheet metal bending machines, 3D Printing, and more. This is the company that will give you the exact custom parts you need.

Contact us today for your quote or to find out more about our services.

Recent Comments