SLA vs FDM

One of the most popular 3D printing topics are debating between SLA vs FDM. Hobbyists most commonly use FDM printers out of affordability, while CNC machinists use SLA out of quality and efficiency.

To back it up, the 3D printer is a tool that creates rapid prototypes through resin or filaments. 3D Printing is an additive manufacturing process, which is the complete opposite of a subtractive process. While subtractive manufacturing processes like laser cutting and metal bending take away from metal to create parts, additive manufacturing builds parts from a 2D model.

Originally known as rapid prototyping, 3D printing is the process of building 3D solid objects from a digital file. G-code is the most common file format. This file contains coordinates to guide the printer’s movements to print the material. These coordinates guide the printer’s movements, both horizontally and vertically, through the x, y, and z axes.

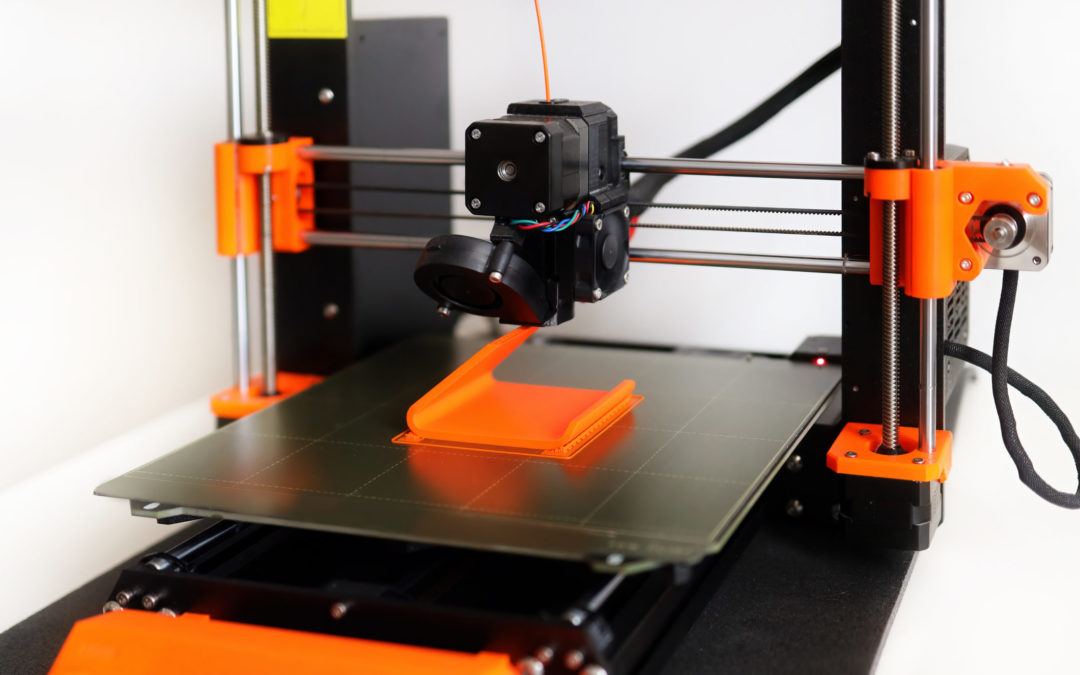

How the FDM 3D Printer Works

The FDM 3D printer acts much like a normal printer. The printer uses the coordinates to print exactly what it is supposed to. The difference is that unlike normal printers, the 3D printer starts at the bottom and slowly builds up to create the object. Since it uses FDM to build layers, it takes a period of hours to turn 2D prints of a 3D CAD drawing into a three dimensional object. The 3D printer must print over the same area in order to create all the necessary details for layering.

Instead of using ink like a normal printer, FDM 3D printers use a nozzle to extrude molten plastic onto the 3D printer’s platform. The computer with the coordinates coming from the software controls the nozzle. The quality of plastic is very important as well. 3D printers use thermoplastic to build the objects.

Thermoplastic becomes liquid when hot and solid when cold. According to ThoughtCo.com, the polymer has the ability to remold and reheat several times. Thermoplastics also have a boiling point between 6500 and 7250 degrees Fahrenheit. This allows 3D printers to easily build and mold objects so easily.

Once the object completely prints, it must go through a post-processing. The process can vary depending on the project. FDM printers require support structures to facilitate 3D printing’s more complex geometries and their removal represents the last step in post-processing. Depending on the extruder type, the object will either have soluble or insoluble support.

FDM 3D Printer Thermoplastics

FDM printers use multiple types of plastics. Yes, you read that correctly. According to British Plastic Federation, there are many different types of thermoplastics. 3D printers use these thermoplastics the most:

- Acrylonitrile Butadiene Styrene (ABS)

- PLA (polylactic acid)

- PETG (polyethylene gerephthalate glycol)

FDM Post-Processing

Once the object completely prints, it must go through a post-processing. Layers cannot always stand on their own though and often need support to remain in the proper position until further layers of the part’s body can be built to stabilize them. FDM post-processing uses two different supports to build. The FDM 3D printer needs two different supports depending on the material used. The machinists need to remove the supports during post-processing.

Insoluble Support

The main material of the 3D object is also in the insoluble supports. FDM 3D printers with a single extruder are the only ones that can use this support. The 3D printer prints the supports from the same filament. Depending on the position of the supports, removing these can be difficult.

Soluble Support

HIPS and PVA most commonly make up soluble supports. ABS uses HIPS, while PLA works with PVA. HIPS dissolves in D-limonene, while PVA dissolves in water. Machinists can easily remove soluble supports by simply soaking the object in water or other liquids. This makes the post-processing very easy.

How the SLA 3D Printer Works

The SLA 3D printer acts much differently than an FDM 3D printer. Unlike FDM printers that use filaments like thermoplastics to print the product from the base to the top, SLA dips the product upside down into the thermoset resin. The printer uses a laser at the bottom of the dish of resin. This light source uses G-Code from the 3D file to coordinate the exact position to permanently cure the resin one layer at a time.

Since it uses SLA to build layers, it takes a period of hours to turn 2D prints of a 3D CAD drawing into a three dimensional object. The 3D printer must dip over the same area of the resin bath in order to create all the necessary details for layering. SLA 3D printers have the highest resolution and accuracy, the sharpest details, and the smoothest surface finishes of all 3D printing technologies. Unlike thermoplastics, thermosets permanently mold after heating.

According to WoodlandPlastics.com, a thermoset monomer must have three or more reactive ends, with its molecular chains crosslinking in three dimensions. Post-molding, thermosets have virtually all molecules interconnected with strong, permanent, physical bonds which are not heat reversible. The SLA 3D printer uses laser UV light to meticulously hit every exact detail of the build.

SLA 3D Printer Thermoset

SLA printers can use many different resins which are thermosets. These are the different types of resins.

- Standard Resin

- Clear Resin

- Tough Resin

- Flexible Resin

- Water-Washable Resin

- Ceramic-Filled Resin

SLA Post-Processing

Once the object completely prints, it must go through a post-processing. The process can vary depending on the project. SLA printers require much more than FDM printers. They need to wash with a specific type of liquid, isopropyl alcohol (IPA) or tripropylene glycol monomethyl ether. This will help avoid the products from being sticky. The machinist can remove the structures after the product is clean.

The machinists use Ultraviolet curing (commonly known as UV curing) to dry the coatings. Ultraviolet curing is a photochemical process in which high-intensity ultraviolet light is used to instantly cure or “dry” inks, coatings or adhesives.

This creates a very smooth finish that has high quality measurements. These SLA parts have very high dimensional accuracy and intricate details.

Overall: SLA vs FDM

SLA vs FDM is a common topic in the 3D printer industry. FDM 3D printers form layers by depositing lines of molten material. In SLA 3D printing, liquid resin is cured by a highly-precise laser to form each layer, which can achieve much finer details and is more reliable to repeatedly achieve high-quality results. SLA uses light and FDM uses heat.

Each have their advantages and disadvantages. It all depends on what you are looking for. Do you want a user friendly and less expensive? Then FDM 3D printing could be the way to go. If you want quality smooth finishes and are ok with longer post-processing, then SLA 3D printing is for you.

If you are in need of a service from either 3D printers types, you should consider Parts Badger. Our 3D printing service will get your parts printed in break-neck speed. Click here to request a quote for your next 3D printing job.

We Are Your Custom Online CNC Machine Shop

Parts Badger creates your exact designed product. We use Instant quoting and 24/7 manufacturing to get your products created and back to you very quickly. Our services include but are not limited to:

Our knowledgeable team of experts will work closely with you to create high-quality components fabricated to your unique specifications, regardless of complexity. Contact us or request your rapid quote today to work with us on your next project.

Recent Comments