Copper Alloys: Defining the different series and their machinability.

Copper alloys offer a wide range of properties such as high corrosion resistance, electrical conductivity, thermal conductivity, strength and ductility. Copper alloys make up many of the recyclable materials that we use along with playing a large role in the electronics that help move along our daily lives. When it comes to machining, pure copper has poor machinability due to high plasticity and toughness. Alloying the copper with elements such as zinc, tin, aluminum, silicon and nickel change the materials composition and can drastically improve machinability.

Copper

Copper (Cu) is one of the few elements that appears in nature in a usable metallic form. It is a soft, malleable and ductile metal that has high thermal and electrical conductivity. It has a pinkish orange color and can be found naturally in many places around the world.

Copper Alloys

In order to enhance or add certain properties, copper is commonly combined with other elements to form copper alloys. Within these alloys, copper is the predominant material but the alloying elements can makeup up over 40% of the alloys composition. The most common alloying element in high amounts is zinc.

Depending on which elements are added to the copper the name of the alloy will also change. The most common copper alloys are brass, bronze, copper-nickel, leaded copper, nickel-silver and gunmetal among many others.

Copper has been in use at least 10,000 years, but more than 95% of all copper ever mined and smelted has been extracted since 1900, and more than half was extracted in the last 24 years

Common Types of Copper Alloys:

High Copper Alloys

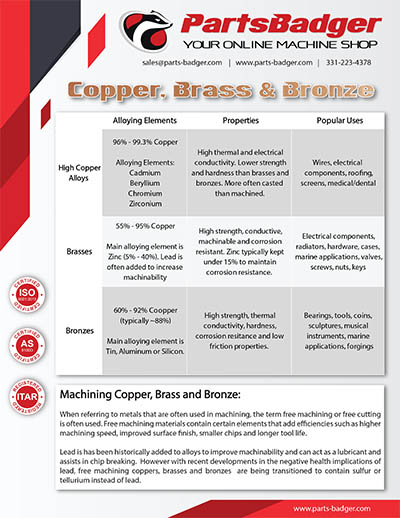

High copper alloys consist of materials containing a copper amount between 96%-99.3%. They maintain the high electrical and thermal conductivity due to the high copper contents but also gain properties of the alloying elements. High copper alloys are used more in casting and forming applications than they are in machining.

Common high copper alloys include:

- Cadmium coppers

- Beryllium coppers

- Chromium coppers

- Zirconium copper

- Chromium-zirconium copper

Brass

When copper is primarily alloyed with zinc it is refereed to as brass. The zinc content can vary but it is typically kept under 15% to maintain corrosion resistance in the alloy. Lead is also added in smaller quantities to increase machinability. Brass is known to be strong, machinable, conductive and corrosion resistant.

Common brasses include:

- Free cutting brass

- Gliding metal (red brass)

- Engraving Brass

- Arsenical brass

- High tensile brass

Bronze

When copper is primarily alloyed with tin, aluminum or sometimes silicon it is refereed to as bronze. Known for high strength, ductility, thermal conduction, hardness, corrosion resistance and low friction properties, bronzes are commonly used in bearings, tools, coins, sculptures and musical instruments.

Common types of bronze:

- Aluminum bronze

- Phosphor bronze

- Nickel silver

- Silicon bronze

- Copper nickel

Machining Copper, Brass and Bronze:

When referring to metals that are often used in machining, the term free machining or free cutting is often used. Free machining materials contain certain elements that add efficiencies such as higher machining speed, improved surface finish, smaller chips and longer tool life.

Lead is has been historically added to alloys to improve machinability and can act as a lubricant and assists in chip breaking. However with recent developments in the negative health implications of lead, free machining coppers, brasses and bronzes are being transitioned to contain sulfur or tellurium instead of lead.

Unified Numbering System (UNS) for Copper and Copper Alloys

Wrought Alloys

Coppers (C10100 – C15999)

High Copper Alloys (C16000 – C19999)

Brasses (C20000 – C49999)

Bronzes (C50000 – C69999)

Copper Nickels (C70000 – C73499)

Nickel Silvers (C73500 – C79999)

Cast Alloys

Coppers (C80000 – C81399)

High Copper Alloys (C81400 – C83299)

Brasses (C83300 – C89999)

Bronzes (C90000 – C95999)

Copper Nickels (C96000 – C96999)

Nickel Silvers (C97000 – C97999)

Leaded Coppers (C98000 – C98999)

Special Alloys (C99000 – C99999)

PartsBadger offers machining of nearly every type of Aluminum Alloy.

Rapid Quote

Enter your material, finish, tolerance, quantity, and upload your file to get your own custom quote in 2-6 hours. The Rapid Quote is perfect for higher volumes or special features.

Instant Quote

Enter your dimensions, material, finish and any other features your part needs and let our Instant Quote algorithm give you immediate pricing.

Contact Us

Need reverse engineering, design services, or just want to work with a design engineer one-on-one? Contact Us Now!