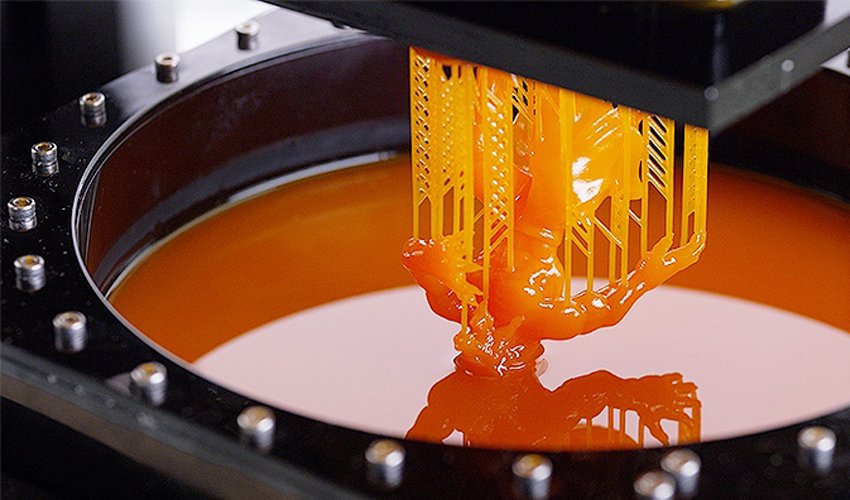

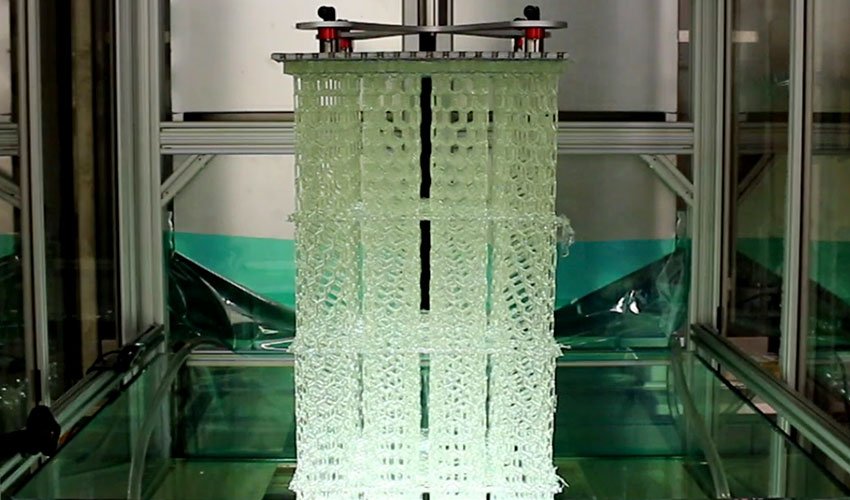

Stereolithography (SLA) 3D Printing

We utilize our SLA 3D printer service to print high quality parts from a variety of resins. SLA 3D printers are capable of printing extremely accurate detailed parts and are great for injection mold like finishes.

SLA 3D printers dip the product upside down into the thermoset resin. The printer uses a light source at the bottom of the dish of resin. This light source uses G-Code from the 3D file to coordinate the exact position to permanently harden the material.

Size Specifications

5.7” x 5.7” x 6.9” (145 x 145 x 175 mm)

File Types

.STP, .STEP, .STL 2D drawing file also required

Tolerances

± 0.0197” (± 0.5 mm)

Material

Our current material options for SLA 3D printing parts include:

- Standard Resin

- White Resin

- Black Resin

- Grey Resin

- Clear Resin

- Castable Wax Resin

- Rigid Resin

- Durable Resin

- Tough Resin

- Flexible Resin

- High Temp Resin.

Post-Processing

Once the object completely prints, it must go through a post-processing. The process can vary depending on the project. They need to wash with a specific type of liquid, isopropyl alcohol (IPA) or tripropylene glycol monomethyl ether. This will help avoid the products from being sticky. The machinist can remove the structures after the product is clean.

The machinists use Ultraviolet curing (commonly known as UV curing) to dry the coatings. Ultraviolet curing is a photochemical process in which high-intensity ultraviolet light is used to instantly cure or “dry” inks, coatings or adhesives.

This creates a very smooth finish that has high quality measurements. These SLA parts have very high dimensional accuracy and intricate details.

Lead Time

We strive to complete your parts at break-neck speed to keep your supply chain in order and get to market.

Quick Quotes

Competitive Prices

No Minimums

Accelerate Your Innovation

We’re here to help you manufacture your machined parts efficiently and timely. We understand the importance of getting your product(s) to market before your competitors do. We provide quotes in hours and most parts in 14-Days or less. Use the form to reach our specialists to request a quote, check on an order status, or to learn more about us and our capabilities. We’re ready to accelerate your innovation.

Information

At PartsBadger, not all of the services we offer relate to a order. We know there is a lot of information out there and a lot of it is helpful. It is part of our mission to make sure the most helpful information is available to our customers. This is why we have compiled the key information about the CNC process, materials, and finishes.

Not sure what material you need? Or maybe you’re not sure what part category your project would fall into? We want to offer the information that will make your project right. So if you do run in to a issue or a question feel free to contact us.

Precision, Quality and Affordability at any volume

In addition to Urethane Casting, our Modern CNC machines can handle small radius cuts and maintain a high quality level whether you want one piece or one hundred. Chamfered edges, multi radius curves, and tapped holes are a few things that make machining a part more workable for any projects. We take pride in making quality, custom, low cost, cast and machined parts.