Learn More About:

Why Choose PartsBadger?

Our commitment to excellence, technological prowess, and dedication to customer satisfaction set us apart.

- Skilled Team: Our experienced machinists and engineers are masters of their craft, ensuring impeccable results.

- Advanced Technology: We invest in the latest CNC machining technology to stay at the forefront of innovation.

- Quality Assurance: Rigorous quality control processes guarantee precision and consistency in every part we produce.

- Timely Delivery: We understand the importance of deadlines and strive to deliver on time, every time.

- Industry Expertise: We have a proven track record of serving diverse industries with specialized solutions.

The CNC Process

CNC (Computer Numerical Control) Machining is referred to as a deductive process mostly used in the manufacturing. It involves the use of computers to control machine tools including lathes, mills, routers and grinders.

When using a CNC machine the first step is creating a CAD design (2D or 3D).That design is then loaded in to the CNC machine. Once the design file has been loaded in to the computer, a code commonly referred to as a G-code, is created to control the machining tools themselves. This code will in essence control features like feed rates, location, coordination and speeds of the CNC machine.

Once a design file is loaded and the code for the CNC has been created a operator will perform a test run. Test runs are performed to ensure the code that was created for the CNC matched the original design. Test runs are also performed to ensure no other issues arise.

After the test run has been completed, the CNC and operator are ready to begin production. At this point materials are loaded in to the CNC and the machining process begins. The process is largely the same whether machining one piece or many.

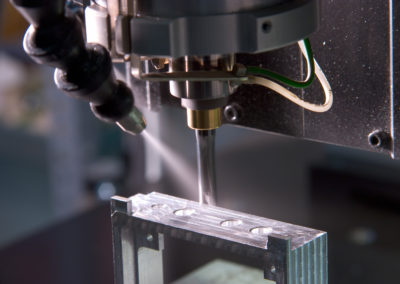

At times to help control heat and debris there may be the addition of a cutting fluid to the process. The fluid is generally sprayed at the machining tool. This extra measure helps ensure neither the tool or material is damaged by heat, and also helps the tools machine with the highest level of control. These fluids generally consist of things like oils, oil-water emulsions, pastes and gels.

There are many advantages to using CNC Machining. The CNC Process is more precise than manual machining, and can be repeated in exactly the same manner over and over again. Because of the precision possible with CNC Machining, this process can produce complex shapes that would be all but impossible to achieve with manual machining. It also lends itself to a vast field of materials, making it easier to turn any 2D or 3D project in to a quality machined result.

It is because of these qualities that CNC Machining is used in jobs that need a high level of precision such as prototype parts. It also ensures precision when a repetitive task like high volume production runs are required. At PartsBadger we take an additional step by creating a quality control sheet based on the original design file. The end result means when ordering with PartsBadger your project will be checked for precision and accuracy before, during and after machining.

Design Consultation

Our experts collaborate with you to understand your project requirements and provide design assistance if needed.

Material Selection

Choose from a wide range of materials, including metals, plastics, and specialty alloys, based on your project’s needs.

Precision Programming

Our skilled programmers create precise machine instructions, optimizing tool paths for maximum efficiency and accuracy.

Machining Execution

State-of-the-art CNC machines bring your designs to life with precision, efficiency, and consistency.

Quality Control

Rigorous quality checks ensure that each part meets your specifications and our stringent standards.

Finishing Options

Enhance the appearance and functionality of your parts with a variety of finishing options, including coatings and surface treatments.

Experience CNC Machining Excellence

Discover the limitless possibilities of CNC machining with [Your Company Name]. Whether you’re prototyping, producing high volumes, or demanding precision tolerances, our capabilities are tailored to bring your ideas to life. Contact us today to discuss your project, request a quote, and experience the future of manufacturing.

Accelerate Your Innovation

We’re here to help you manufacture your machined parts efficiently and timely. We understand the importance of getting your product(s) to market before your competitors do. We provide quotes in hours and most parts in 14-Days or less. Use the form to reach our specialists to request a quote, check on an order status, or to learn more about us and our capabilities. We’re ready to accelerate your innovation.