Kerf is the width of material that is removed by a cutting process, such as CNC milling or hand-cutting with a saw. The term was originally used to describe how much wood was removed by a saw. A saw’s teeth are bent to the side so that they remove more material than the width of the saw blade itself. This prevents the saw from getting stuck in the wood, this leaving a kerf (width) of removed material.

Kerf is the width of material that is removed by a cutting process, such as CNC milling or hand-cutting with a saw. The term was originally used to describe how much wood was removed by a saw. A saw’s teeth are bent to the side so that they remove more material than the width of the saw blade itself. This prevents the saw from getting stuck in the wood, this leaving a kerf (width) of removed material.

The word gets it’s origins from Middle English “kerf, kirf, kyrf”, from Old English “cyrf” (“an act of cutting, a cutting off; a cutting instrument”), from Proto-Germanic “kurbiz” (“a cut; notch”), from Proto-Indo-European “gerb” (“to scratch”).

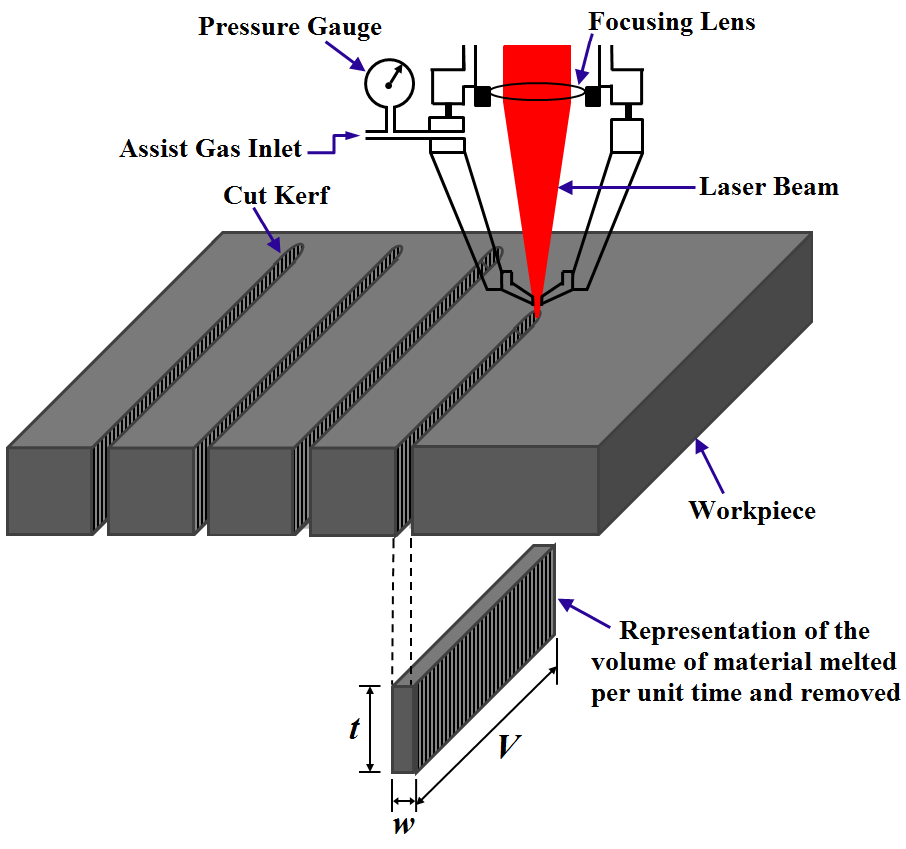

A kerf can also be created from CNC shape cutting with typical cutting processes.

Methods

Almost all cutting mechanisms leave a cutting kerf, e.g laser cutting, plasma cutting and other thermal cutting methods. But also mechanical cutting processes like sawing. Here are the most common ones:

Almost all cutting mechanisms leave a cutting kerf, e.g laser cutting, plasma cutting and other thermal cutting methods. But also mechanical cutting processes like sawing. Here are the most common ones:

- CNC Miling

- Mechanical Saw Cutting

- Hand Saw

- Laser Cutting

- Plasma Cutting

- Waterjet

- Oxy-Fuel Cutting

Each cutting process produces a different width. The following demonstrates the smallest kerf a process may produce:

- CNC cutting produces a wide range of widths depending on the tooling

- Mechanical and Hand Saws are 3.175mm

- Laser cutting is around .3mm, providing the smallest and most accurate cutting method

- Plasma cutting is around 3.8mm

- Waterjet cutting is around .9mm

- Oxy-fuel cutting (flame) is around 1.1mm

Width is Critical

When cutting parts on a CNC plasma or laser machine, you want to produce accurate cut parts. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. So the actual tool path has to be compensated by 0.100” to the side of the programmed path, all the way around the part.

When cutting parts on a CNC plasma or laser machine, you want to produce accurate cut parts. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. So the actual tool path has to be compensated by 0.100” to the side of the programmed path, all the way around the part.

Rather than re-program the part at a different dimension, the CNC will take care of this automatically just by telling it which direction to offset. Most modern CNCs take the actual kerf amount and automatically offset the tool path by 1/2 of that amount. The finished part comes out very close to the programmed dimensions. That is why the value is often referred to as “kerf offset”.

Variations

Not only does the width vary from one process to the next, but there are lots of things that affect the width for each process. Of course, as the thickness of material increases, it takes more power to cut through it. In the case of plasma, that means higher current and a larger nozzle. Laser increases power. Oxy-fuel cutting uses a larger nozzle with a wider cutting oxygen stream and hotter preheats. Waterjet uses either a larger nozzle/orifice combination, or a slower cutting speed. Regardless of the process, as the plate gets thicker, the kerf gets wider.

There are variations within each process too. For example, when plasma cutting, the actual kerf width depends not only on the cutting current, but also on the torch height, speed, and gas settings.

How Offset is Adjusted

Kerf offset is traditionally adjusted manually by the machine operator at the CNC. Prior to running a program, the operator must enter the width so that the CNC can calculate the actual tool path required to cut the part to the correct dimensions.

Modern thermal cutting and waterjet machine controls will also allow the kerf width value to be included in the part program, or to be called from a process database stored in the CNC. This makes it much easier for operators, since they don’t need to look up the values for each material type and thickness they cut, but rather they simply select the material type and thickness, then the CNC looks up all of the process variables in the database.

If you have any questions about your next project and matching the correct kerf width with the correct method, we can be reached at [email protected].

Recent Comments