The Complete Guide to Processes, Materials, and Innovations

What is Metal Fabrication? A Full Review

Metal fabrication is the process of crafting intricate and useful items from raw metal. It involves cutting, forming, welding, and finishing metal to create products ranging from skyscrapers to kitchen utensils. Key techniques include the use of lasers, plasma torches, and advanced materials like steel and aluminum, along with innovations such as 3D printing and AI, making it a cornerstone of modern manufacturing.

- Introduction to Metal Fabrication

- The Processes of Metal Fabrication

- Materials Used in Metal Fabrication

- Technological Innovations in Metal Fabrication

- Challenges and Solutions in Metal Fabrication

- The Future of Metal Fabrication

Introduction to Metal Fabrication

Ever wondered how a chunk of metal turns into something so useful and intricate? Welcome to the world of metal fabrication! This process is all about creativity and precision, transforming raw metal into products we use every day.

- What is Metal Fabrication? Simply put, it’s a craft. Metal fabricators cut, bend, and assemble metal to create structures or parts. It’s not just about heavy machinery; it’s about bringing blueprints to life.

From skyscrapers to your kitchen spoons, metal fabrication is behind many of the things you see and use. “Metal fabrication is the backbone of the modern manufacturing industry,“ says an expert in the field. This process plays a crucial role in various sectors, including construction, automotive, and aerospace.

Engaging with metal fabrication means you’re engaging with a world of endless possibilities. Whether it’s a custom piece for your home or a critical part for a machine, metal fabrication makes it all possible with a blend of technology and human skill.

The Processes of Metal Fabrication

Metal fabrication is all about turning metal into useful, often complex, parts and structures. Let’s dive into how this is done!

- Cutting: This is where it all starts. Big pieces of metal are cut down to size using lasers, plasma torches, or water jets. Each method has its own perks, but they all get the job done.

- Forming: After cutting, metal sheets are bent into shapes. This might be done through pressing between dies or by hammering.

- Welding: One of the most critical steps in metal fabrication. This process involves fusing metal pieces together using heat and sometimes adding a filler material to ensure a strong bond.

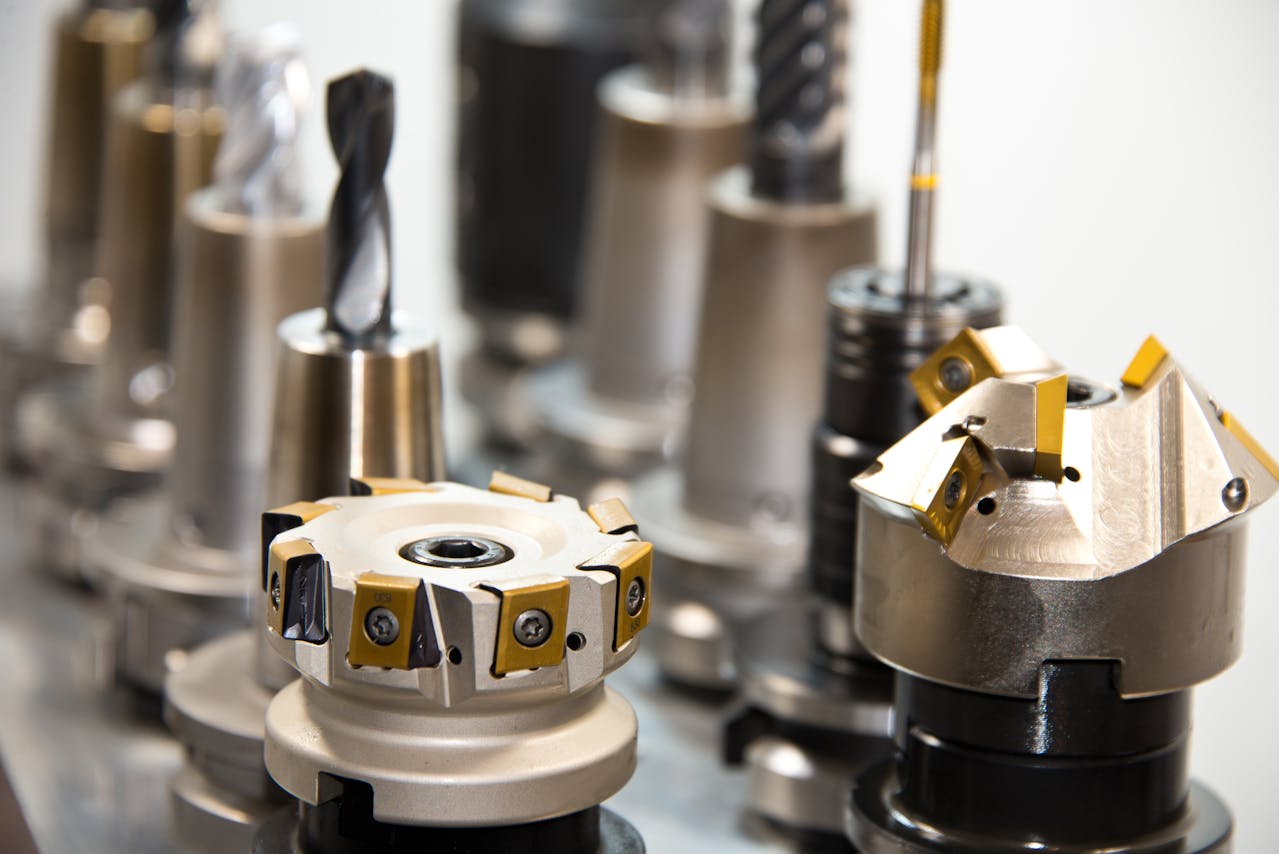

- Machining: Here, fabricators remove parts of the metal to achieve the desired shape. It’s like sculpting, but with metal!

- Finishing: The final touch involves polishing or coating the metal to improve its appearance and resistance to corrosion.

“Metal fabrication is not just a process; it’s an art that requires precision and innovation,” says an industry expert. Each step is crucial for creating durable and precise products, making metal fabrication an essential service in countless industries.

Materials Used in Metal Fabrication

In the world of metal fabrication, the choice of materials is as vast as it is vital. Each material brings its own set of strengths and weaknesses, shaping the outcome of every project.

- Steel: The backbone of many metal fabrication projects, known for its durability and strength.

- Aluminum: Loved for being lightweight yet strong, aluminum is a favorite in automotive and aerospace industries.

- Copper: Highly valued for its electrical conductivity, making it indispensable in electrical components.

- Brass: Often used for its decorative appeal, as well as its resistance to corrosion.

- Titanium: Though pricey, it’s unbeatable for its strength-to-weight ratio and corrosion resistance.

“The materials we choose in metal fabrication directly influence the performance and durability of the final products,” explains a seasoned fabricator. This quote highlights the critical role materials play in the success of metal fabrication projects. As technology advances, so too do the options for materials, allowing for more innovative and efficient fabrication processes. The future of metal fabrication looks bright, with new materials and techniques constantly on the horizon.

Technological Innovations in Metal Fabrication

Metal fabrication is stepping into the future with some exciting technological innovations. These advancements are not just cool; they’re revolutionizing the way we create and construct. Here’s a peek into how tech is changing the game:

- Automation and Robotics: Imagine machines that can work almost like humans but faster and without tiring. Automation in metal fabrication means more precise cuts and consistent outputs, every single time.

- 3D Printing: Once a fancy concept, 3D printing is now a powerhouse in metal fabrication. It allows for complex parts to be made quicker and cheaper than ever before. According to a recent article on Forbes, “3D printing is transforming metal fabrication from the ground up.”

- AI and Machine Learning: These smart technologies are making metal fabrication smarter. AI can predict when machines need maintenance before they break down. This means less downtime and more productivity.

- Green Technologies: As the world leans towards sustainability, metal fabrication isn’t left behind. Innovations like solar-powered machines and recyclable materials are making the process eco-friendlier.

These innovations are not just changing how things are made but also improving efficiency and sustainability in metal fabrication. The future looks bright and full of possibilities!

Challenges and Solutions in Metal Fabrication

Metal fabrication isn’t all smooth sailing; it’s got its fair share of hurdles. But, like any crafty industry, it’s chock-full of clever solutions too. Here’s what shakes up the world of metal fabrication and how the pros tackle these issues:

- Material Costs: The price of raw materials can fluctuate wildly, which makes budgeting a bit like trying to hit a moving target. To combat this, savvy companies hedge their bets by bulk buying or locking in prices with suppliers when costs are low.

- Skilled Labor Shortage: Finding folks who can expertly weld and craft isn’t a walk in the park. Many companies invest in training programs, ensuring a steady stream of skilled workers. As one industry leader put it, “We’re not just building parts; we’re building futures.”

- Technological Adaptation: Keeping up with the latest tech can be daunting but essential. Companies often phase in new technologies, training staff along the way to ensure smooth transitions.

- Regulatory Compliance: Staying on top of industry regulations requires constant vigilance. Successful fabricators use compliance as a stepping stone rather than a stumbling block, integrating it into their processes from the get-go.

Each challenge in metal fabrication comes with a smart strategy to tackle it. Innovations and forward-thinking approaches keep the industry not just surviving, but thriving.

The Future of Metal Fabrication

As we look ahead, the future of metal fabrication shines with potential. This dynamic field is set to transform with advancements that promise to redefine how we create and innovate.

- Automation and Robotics: The integration of automation and robotics is revolutionizing metal fabrication. These technologies ensure precision and speed, reducing human error and boosting productivity.

- Greener Practices: There’s a growing push towards sustainable practices in metal fabrication. Innovations in materials and processes are paving the way for more environmentally friendly production methods.

- Advanced Materials: The exploration and use of new materials continue to open up possibilities. These materials offer improved performance and can withstand more extreme conditions.

“With every innovation, metal fabrication becomes more efficient, precise, and environmentally conscious,” says an industry expert. This quote captures the essence of progress in this sector.

The implications of these advancements are profound, affecting everything from production speed to the environmental impact of fabrication. As we move forward, the metal fabrication industry is poised to meet modern demands with remarkable agility and innovation.

Discover the unmatched precision and quality of metal fabrication with PartsBadger. Our commitment to excellence and innovation in metal fabrication sets us apart in the industry, making us the go-to choice for businesses seeking reliable and efficient manufacturing solutions. At PartsBadger, we understand the complexities and challenges of metal fabrication and have tailored our services to meet the diverse needs of our clientele. From intricate component design to large-scale production, our state-of-the-art technology and skilled team ensure that every project meets the highest standards of quality and performance. Our ability to adapt and respond to customer needs quickly without compromising on quality is what makes us a leader in the field. Choose PartsBadger for your metal fabrication needs and experience a partnership that values precision, speed, and customer satisfaction above all else. Let us help you achieve your manufacturing goals with our cutting-edge technology and innovative approaches. Trust PartsBadger to deliver not just products, but solutions that power your success in an ever-evolving market.