We know your parts don’t just need to be accurate, they need to look and perform exactly as intended. We offer a variety of surface finishes and coatings to meet aerospace, medical, automotive, industrial, and consumer product requirements. Whether you’re looking for cosmetic appeal, improved wear resistance, corrosion protection, or specific tactile qualities, we have the right finishing process for your project.

After machining, sharp edges and burrs can affect part performance and safety. Our deburring process removes these imperfections, leaving you with a clean, functional surface. This is our standard finish — no additional polishing or texturing applied.

Internal components, functional prototypes, parts not requiring cosmetic enhancement.

Removes most machining marks while leaving a slightly textured surface. Minor scratches may remain but can be further improved with fine-grit wet sanding and polishing.

Parts that require a smoother look without full cosmetic perfection.

Glass beads are blasted at high pressure to create a uniform, matte finish.

Aerospace housings, consumer products, and components needing a consistent, glare-free finish.

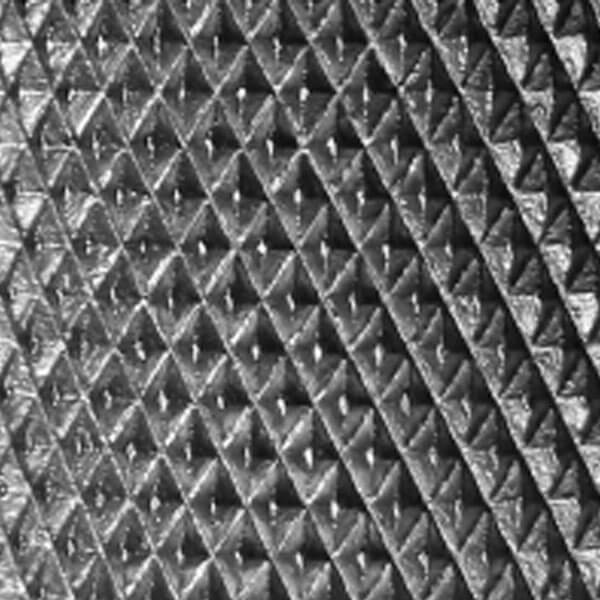

Adds a patterned grip surface to cylindrical parts for better handling. Commonly used on knobs, handles, and fasteners.

Tooling, control surfaces, and products requiring tactile grip.

Creates a fine, directional grain pattern on the part surface, offering both visual appeal and scratch-hiding capabilities.

Decorative aerospace panels, electronics enclosures, and consumer goods.

Uses abrasive media to smooth edges, reduce surface roughness, and provide a uniform matte finish.

Bulk finishing of small parts and deburring delicate geometries.

The best finish depends on your material, application, and desired appearance. Our engineers can help you select a surface treatment that optimizes both performance and aesthetics.