Properties of Titanium Ti-6Al-4V (Grade 5):

Grade 5 Titanium is one of the most popular alloys in the titanium industry and makes up almost half of the titanium used in the world. Commonly referred to as Ti-6AL-4V (or Ti 6-4), this designation refers to its chemical composition of almost 90% titanium, 6% aluminum, 4% vanadium, 0.25% (max) iron and 0.2% (max) oxygen. It has excellent strength, low modulus of elasticity, high corrosion resistance, good weldability and it is heat treatable. The addition of aluminum and vanadium increases the hardness of the material in the alloy matrix, improving its physical and mechanical properties.

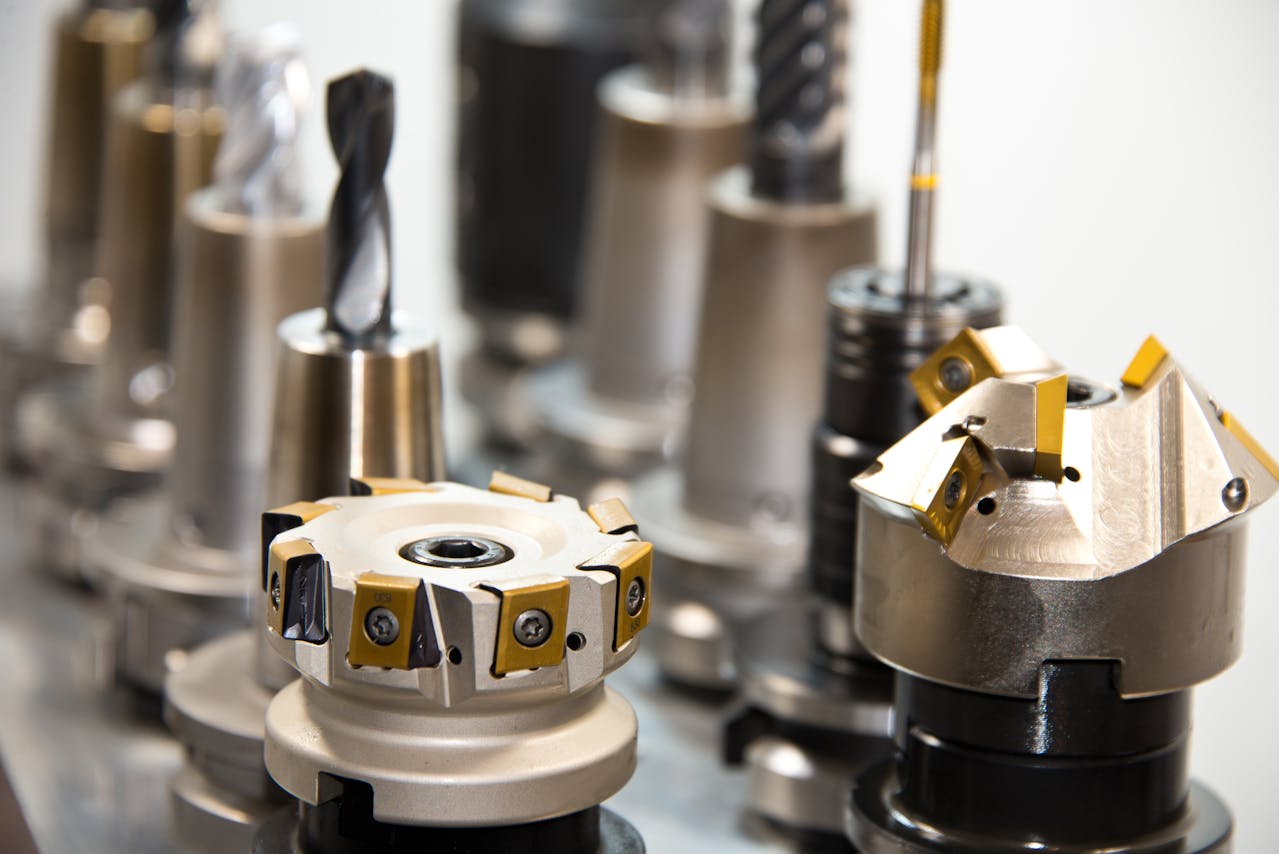

- High tensile strength—Ti 6Al-4V’s strength nears

that of stainless steel, requiring high cutting

forces. - Low thermal conductivity—Heat does not readily

transfer into the chip but rather flows into the

cutting tool, which makes the cutting edge very

hot during the machining process.

- High modulus of elasticity—Titanium is very

“springy.“ For a given force, it will deflect more

than steel, which results in a higher likelihood of

vibration, chatter, and poor chip formation. - Shear mechanism—Titanium requires a sharp

cutting edge to cut the material and avoid tearing

and smearing, which will quickly lead to tool

failure

| Mechanical Properties | Metric | English |

| Hardness, Brinell | 379 | 379 |

| Hardness, Knoop | 414 | 414 |

| Hardness, Rockwell C | 41 | 41 |

| Hardness, Vickers | 396 | 396 |

| Tensile Strength, Ultimate | 1170 MPa | 170000 psi |

| Tensile Strength, Yield | 1100 MPa | 160000 psi |

| Elongation at Break | 10 % | 10 % |

| Modulus of Elasticity | 114 GPa | 16500 ksi |

| Compressive Yield Strength | 1070 MPa | 155000 psi |

| Notched Tensile Strength | 1550 MPa | 225000 psi |

| Ultimate Bearing Strength | 2140 MPa | 310000 psi |

| Bearing Yield Strength | 1790 MPa | 260000 psi |

| Poisson’s Ratio | 0.33 | 0.33 |

| Charpy Impact | 23 J | 17 ft-lb |

| Fatigue Strength min | 160 MPa | 23200 psi |

| Fatigue Strength max | 700 MPa | 102000 psi |

| Fracture Toughness | 43 MPa-m½ | 39.1 ksi-in½ |

| Shear Modulus | 44 GPa | 6380 ksi |

| Shear Strength | 760 MPa | 110000 psi |

| Electrical Properties | Metric | English |

| Electrical Resistivity | 0.000178 ohm-cm | 0.000178 ohm-cm |

| Magnetic Permeability | 1.00005 | 1.00005 |

| Magnetic Susceptibility | 3.3e-006 | 3.3e-006 |

| Thermal Properties | Metric | English |

| CTE, linear 20°C | 8.6 µm/m-°C | 4.78 µin/in-°F |

| CTE, linear 250°C | 9.2 µm/m-°C | 5.11 µin/in-°F |

| CTE, linear 500°C | 9.7 µm/m-°C | 5.39 µin/in-°F |

| Specific Heat Capacity | 0.5263 J/g-°C | 0.126 BTU/lb-°F |

| Thermal Conductivity | 6.7 W/m-K | 46.5 BTU-in/hr-ft²-°F |

| Melting Point | 1604 – 1660 °C | 2920 – 3020 °F |

| Solidus | 1604 °C | 2920 °F |

| Liquidus | 1660 °C | 3020 °F |

| Beta Transus | 980 °C | 1800 °F |