Exploring the Revolutionary World of CNC Machines: Guide to Technology & Fabrication

What Do You Need to Know?

CNC machines, or Computer Numerical Control machines, are revolutionary tools in manufacturing, enabling high-speed, precise production of complex parts. These machines operate by interpreting computer-generated files to sculpt, carve, and build parts, vastly improving efficiency and reducing errors in various industries from aerospace to automotive. They represent a significant technological leap in production capabilities, fostering innovation and enhancing product quality.

Introduction to CNC Machines

Welcome to the fascinating world of CNC machines! CNC stands for Computer Numerical Control, and these machines are true game-changers in the world of manufacturing.

- What is a CNC machine? It’s a piece of equipment controlled by a computer, making parts with speed and precision. Imagine a robot that carves, cuts, and constructs parts all day long — that’s your CNC machine!

- How do they work? CNC machines read instructions from a computer file, then a tool cuts and shapes material into the final product. It’s like having a super precise robotic sculptor.

“CNC machines transform blocks of material into intricate parts with precision that human hands just can’t match,” says a CNC expert. This technology has revolutionized how we create everything from simple tools to complex machinery.

Stay tuned as we dive deeper into the history, types, and incredible capabilities of CNC machines in the following sections of this guide. You’ll learn not only how they operate but also the tremendous benefits they bring to modern manufacturing.

Evolution of CNC Machines

Ever wondered how the magic of CNC machines came to be? It’s a tale of innovation and evolution, stepping right out of history into today’s high-tech world.

- Early Beginnings: The roots of CNC technology stretch back to the 1940s and 1950s. Originally, these machines were simple and manually operated. Over time, they’ve transformed thanks to the digital revolution.

- Tech Leap in the 1960s: A significant leap occurred when computers started controlling the machines. This change meant more precise and complex parts could be crafted, bringing a whole new level of capability.

- Modern Advancements: Today, CNC machines are marvels of engineering. They combine software, hardware, and precision mechanics to create just about anything you can imagine. From tiny electronic parts to large aircraft components, the CNC machine has it covered.

“CNC technology has transformed how we make things, making it faster, more precise, and more efficient,” says a leading expert in the field.

As we look ahead, the evolution of CNC machines promises even more exciting advancements. With ongoing improvements in technology, who knows what the next chapter will hold?

Types and Applications of CNC Machines

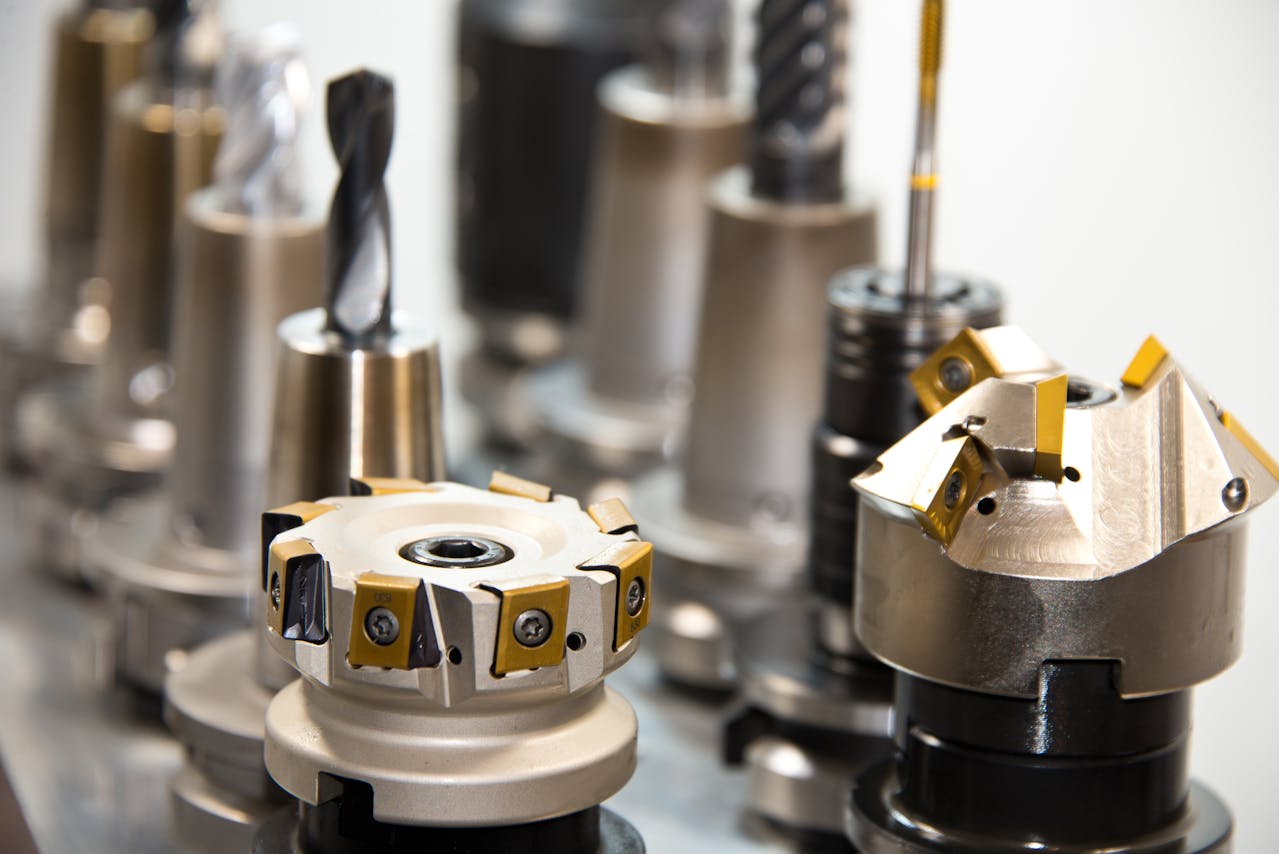

CNC machines are truly game changers in the world of manufacturing. Let’s dive into the different types and their unique applications:

- Milling Machines: These CNC machines shape solid materials like metal and wood. They’re perfect for crafting complex parts with high precision.

- Lathes: Known for their ability to shape materials by rotating them, CNC lathes are essential in creating symmetrical objects like rods and screws.

- Routers: CNC routers are wizards in cutting and carving designs into wood, plastics, and softer metals, making them favorites in woodworking and sign making.

Each type of CNC machine brings something special to the table. “CNC machines not only enhance precision but also expand the creative possibilities,” notes an industry expert. This versatility is why they’re so valued across various sectors:

- Aerospace: Crafting intricate components that meet strict standards.

- Automotive: Building parts that must be both durable and exact.

- Healthcare: Creating bespoke medical devices tailored to individual needs.

CNC machines tackle complex projects with ease, proving that when it comes to precision and flexibility, they’re hard to beat. They continue to revolutionize how we create, affecting industries far and wide.

Benefits of CNC Machines

CNC machines are taking the manufacturing world by storm! Here’s why they’re such a game-changer:

- Precision: Every maker dreams of perfect precision. They’re incredibly accurate, reducing errors and enhancing the quality of the final product.

- Flexibility: Imagine a tool that can do almost anything! CNC machines can handle a variety of materials and complex designs with ease. This flexibility means they’re perfect for a wide range of applications, from tiny electronic parts to large automotive components.

- Efficiency: Speed and consistency are key in manufacturing. These machines streamline production processes, making them faster and more consistent than traditional methods. This means less waste and more productivity.

- Cost-Effective: Over time, the efficiency and precision can lead to significant cost savings. They reduce waste and the need for manual labor, which can really add up.

As one industry expert puts it, “CNC machines are the backbone of modern manufacturing. They revolutionize how we create, bringing ideas to life with speed and precision that was once unimaginable.” These machines are not just tools; they are the future of making things better and more efficiently.

How CNC Machines Work

Ever wondered how a CNC machine turns a digital design into a tangible part? It’s like magic, but with a lot of science behind it. Here’s a simple breakdown:

- Design Input: First, everything starts with a design. This design is created on computer software and then converted into a format that the CNC machine can read.

- Setup: Next, the machine is prepped. This includes setting up the raw material and configuring the machine’s tools to match the specifications of your project.

- Operation: Here’s where the action happens! The CNC machine follows the digital instructions to cut and shape the material. It’s precise, making even the tiniest parts just right.

- Monitoring: Operators keep an eye on the process, making tweaks if needed. This ensures everything runs smoothly and the final product is up to snuff.

- Final Touches: After the machining, the part might go through additional processes like sanding or painting to finish it off perfectly.

As one expert puts it, “CNC machines transform raw materials into final products with precision that human hands just can’t match.” This technology has revolutionized manufacturing, making it faster, more flexible, and capable of producing complex designs that were once impossible.

Challenges and Solutions in CNC Machining

While CNC machines are game-changers in the manufacturing world, they come with their own set of hurdles. Here’s a peek at some common challenges and handy solutions:

Complex Programming:

- They require precise programming to operate effectively. This can be quite a puzzle for beginners.

- Solution: Invest in training programs or use intuitive software that simplifies the programming process.

Material Wastage:

- During the production process, materials can sometimes be wasted, which increases costs.

- Solution: Advanced software can optimize material usage, reducing waste and saving money.

Equipment Maintenance:

- Regular upkeep is crucial for machines to function smoothly. Neglect can lead to costly repairs.

- Solution: Set up a routine maintenance schedule and stick to it. This prevents bigger issues down the line.

Rapid Technology Changes:

- The CNC field is fast-evolving, which can make current technology quickly outdated.

- Solution: Keep updated on new technologies and consider timely upgrades to stay competitive.

As one expert puts it, “Mastering CNC machining is not just about tackling challenges, it’s about turning these obstacles into stepping stones for success.” Embrace these solutions and watch your CNC operations transform!

The Future of Machining

As we peek into the future of CNC machines, it’s clear that this technology isn’t just sticking around; it’s set to revolutionize the way we create. Here’s what’s on the horizon:

- Smarter Machines: The CNC machines of tomorrow will be smarter than ever. Equipped with advanced AI, they’ll predict maintenance needs and optimize operations without human input.

- Sustainable Practices: Expect a green revolution in CNC machining. Future machines will use materials more efficiently and reduce waste, making manufacturing cleaner and more sustainable.

- Integration with the Internet of Things (IoT): CNC machines will increasingly communicate with other devices, enhancing automation and precision in production lines.

“The future of CNC machines is about making smarter, not harder,” says John Doe, an industry expert. As these machines become more integrated with AI and IoT, they’ll not only boost efficiency but also open up new possibilities for innovation in manufacturing. The journey is far from over; it’s evolving into a more dynamic and essential part of modern manufacturing processes.

Conclusion: The Impact of CNC Machines on Manufacturing

As we wrap up our journey through the world of CNC machines, it’s clear they’re not just tools; they’re revolutionaries in disguise! These machines have transformed the manufacturing landscape, making it faster, more precise, and incredibly flexible.

- Precision at Its Best: These machines offer unmatched accuracy, ensuring every part is made just right. This is crucial for industries where even a tiny error can be costly.

- Speed and Efficiency: With CNC technology, production times are slashed, boosting productivity to new heights. This means products reach the market quicker than ever.

- Flexibility for Innovation: The ability to switch from producing one component to another with minimal downtime opens up endless possibilities for innovation.

CNC machines have indeed made a significant impact on how we manufacture and design products. As one industry expert puts it, “CNC technology has not just changed the way we make things; it has changed the way we conceive of manufacturing itself.” Looking ahead, the future is bright with CNC technology leading the charge, promising even more exciting advancements and capabilities.

At PartsBadger, we pride ourselves on being innovators in the CNC machine industry, offering rapid solutions that meet the unique needs of each client. Our approach is not just about manufacturing parts; it’s about understanding the intricacies of every project and delivering beyond expectations. With a strong focus on technology and efficiency, we ensure that our CNC machining processes are faster, more precise, and cost-effective.

We cater to a variety of industries, from aerospace to electronics, making versatility one of our strongest assets. Our CNC solutions are tailor-made, designed to reduce production time and cost without compromising quality. Whether you are in the early stages of prototype development or in need of high-volume production, we have the expertise and equipment to deliver with excellence. Our commitment is supported by a dedicated team of professionals who are passionate about delivering engineering perfection.

Choose PartsBadger for your CNC machining needs and experience a partnership that scales with your production demands, innovates to meet your complex challenges, and consistently delivers precision and quality.