A deep hole is classified by having at least a 10:1 depth-to-diameter ratio.

Special cutting tools are needed for deep hole drilling to allow for an increased amount of coolant to flow in and out of the hole in order to evacuate chips. For most deep hole drilling applications, specialized machines that consist of dual spindles which rotate the workpiece along with the cutting tool are also required.

The two primary methods of deep hole drilling are BTA drilling and gun drilling

For parts with interior threads called out, heat-set threaded inserts will be added post printing. The part files will need to be modified to accept these inserts and our engineers will review all parts to ensure compatibility. Most common thread sizes are available and we can perform the file modifications for an additional cost.

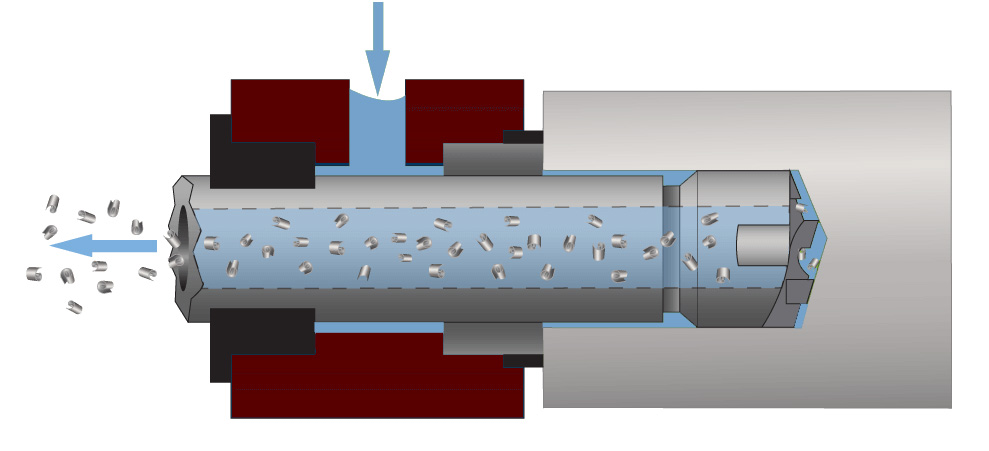

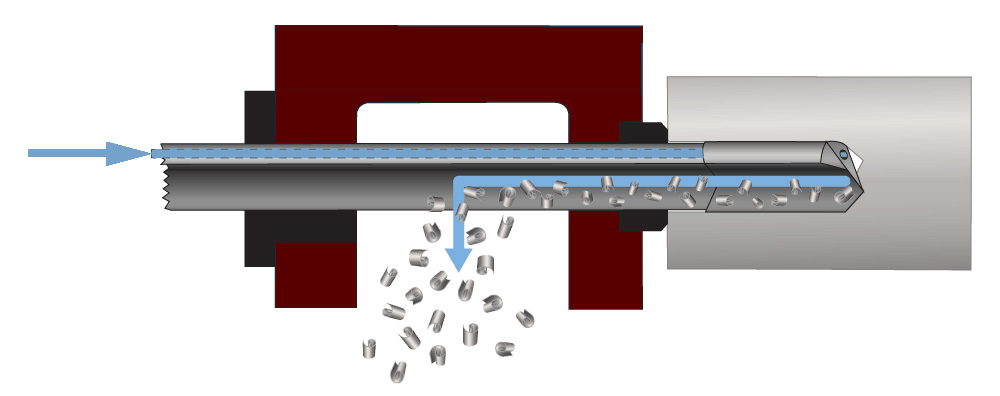

Gun Drilling is a deep hole drilling method which uses a long, thin cutting tool to produce highly accurate and straight holes in work pieces beyond what conventional style drills are capable of. Gun drills differ from conventional drills by having a single straight flute cutting edge and a single internal coolant hole. Pressurized coolant is fed through the internal hole and chips are evacuated through the single flute along the shank.

Depending on the depth-to-diameter ratio of the hole, some gun drilling processes can be completed on a standard CNC machine. However the majority of gun drilling applications are done on a specialized machine and in some cases can reach extreme depth-to-diameter ratios of up to 400:1.

Our online portal can provide instant quotes.

Whether you need one part or thousands.

High quality without inflated markups.

We’re here to help you manufacture your machined parts efficiently and timely. We understand the importance of getting your product(s) to market before your competitors do. We’re ready to accelerate your innovation.