Laser cutting has been around since the 60s and for good reason. It’s still going strong in 2022 as one of the most popular industrial cutting methods available today. Here are 4 benefits of adding laser cutting to your supply chain.

1) Laser Cut Parts will Ensure Consistency

Laser cut parts will ensure consistency. According to Laser 24, laser cutters use nitrogen, oxygen, and air to cut the parts. This allows for less energy to cut more parts. With a fixed blade, it will not matter who does the work. The cuts will always be consistent regardless of who makes them. Each part is exactly the same every time. This will save time and money in assembly as well as make replacement parts easy to find and order.

The company’s supply chain runs efficiently by using off-the-shelf parts that are easily accessible. This means that you can quickly create custom parts without having to design and build molds or tooling each time you need something new.

2) Laser Cut Parts can be Produced Quickly

You can produce laser cut parts quickly. Use this when you need to get a supply chain moving, speed up production and ship faster. This is an important benefit of laser cutting that logistics overlooks. Instead of waiting for conventional manufacturing processes to complete, order fulfillment can happen almost immediately. In some cases, it’s possible to custom-make parts in hand within 24 hours or less—which means you can skip over many steps in your supply chain with zero wait time between them.

How will that benefit your business? Take a closer look at five of our favorite reasons why we feel so strongly about these benefits, and how they can help you in today’s competitive marketplace.

3) Different Variety of Materials

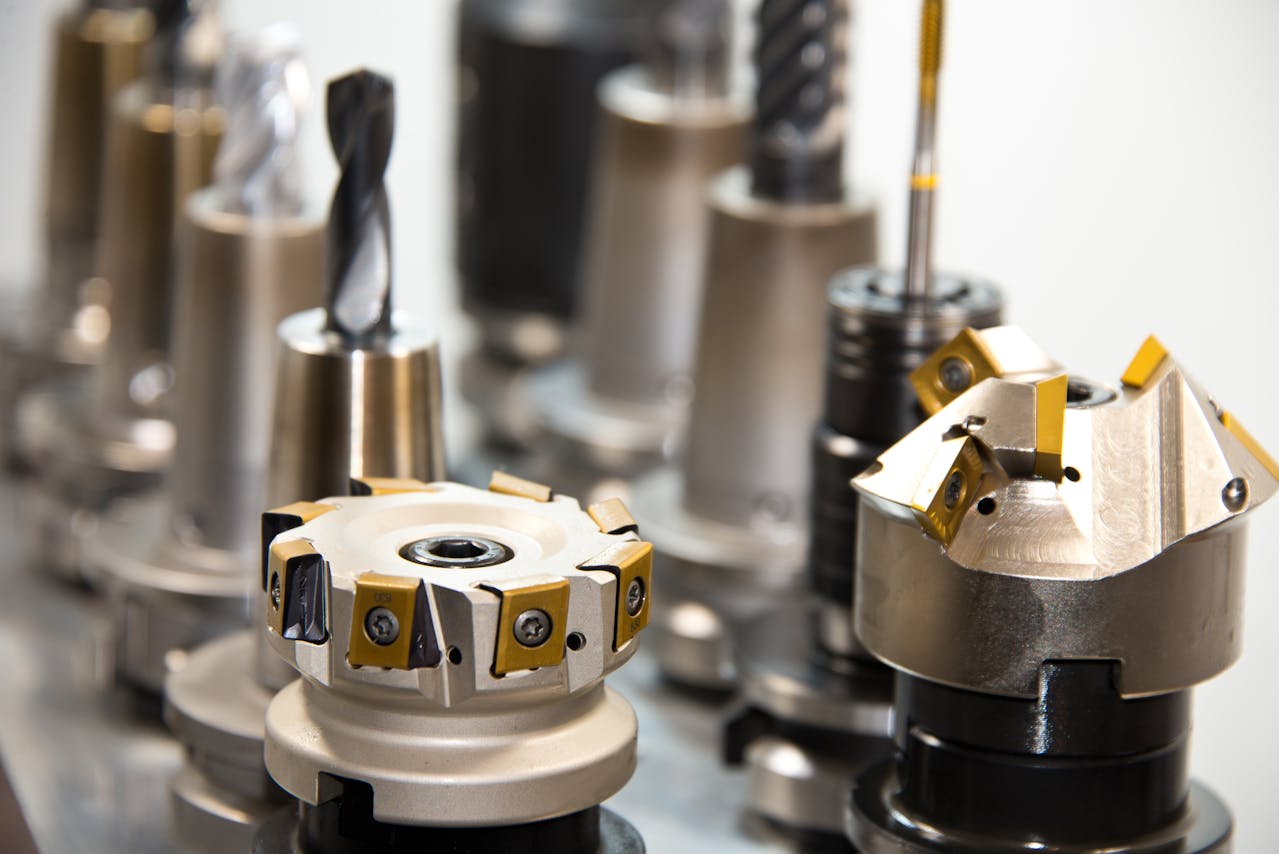

Often engineers refer laser cutting as the step child of additive manufacturing. 3D printing doesn’t hold a candle to the benefits that come with high-powered laser cutting. When your supply chain needs fast, safe and efficient ways to get goods made, you need laser cutters. While 3D printers excel at producing shapes and prototypes of plastic objects, they can often fail on complex pieces with lots of angles or curves.

Laser cutters excel at producing complex shapes and prototypes from a wide range of materials. They use laser cutters to create metal parts, such as brackets, gears and machine parts. These parts are either too small or too intricate to fabricate with traditional techniques. Laser cutters can also work with a wide variety of plastics and acrylics, even if they’re colored.

4) Laser Cut Parts Are Affordable

Laser cut parts are affordable because they are precision cuts and can be made out of many different materials such as metal, plastic, and other exotic materials. Laser cut parts also have an advantage over waterjet cut parts in that it doesn’t waste so much material. When using a waterjet to do your intricate cuts you end up wasting a lot of excess material which isn’t good if you need to make multiple copies of a single product.

But what if you’re looking to make larger parts that need an intricate design? This can be accomplished as well with a CNC machine, however these machines are more expensive and harder to work with. Laser cut parts have been used in a lot of different industries because they can be affordable, fast, and precise all at once.

Why You Should Have PartsBadger Supply Your Needs

PartsBadger offers instant quotes, CNC parts with varying depths, no minimum order quantity and instant lead times. You can also choose exactly what you want on a part, this means you get what you want rather than getting what they have. Most importantly parts are always 100% custom so you know that every part you receive was made just for you.