Multi-axis machining is a cutting-edge technology that redefines the possibilities of CNC manufacturing. At PartsBadger, we’re proud to offer this advanced capability that allows us to create intricate and complex parts with unparalleled precision.

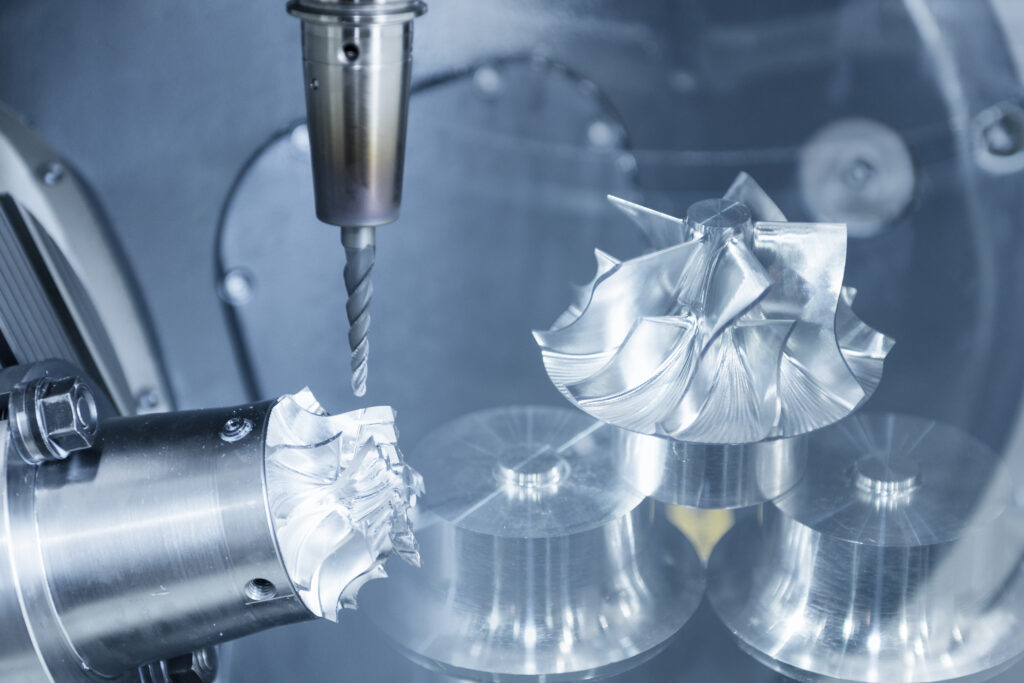

Multi-axis machining, often referred to as 3-axis, 4-axis, or 5-axis machining, goes beyond the traditional X, Y, and Z axes of CNC machining. It involves simultaneous movement of the cutting tool along multiple axes, allowing for more intricate and complex geometries that traditional machining can’t achieve.

The aerospace industry demands intricate shapes & contours. Multi-axis machining allows us to create turbine blades, airfoils, and structural components with precision.

Medical instruments and implants often require complex shapes and tight tolerances. Multi-axis machining ensures these parts meet high standards.

From engine components to intricate interior parts, multi-axis machining is used to create both functional and aesthetic elements in the automotive sector.

Multi-axis machining is perfect for creating prototypes of complex designs, enabling engineers to validate concepts before moving to production.

Our online portal can provide instant quotes.

Whether you need one part or thousands.

High quality without inflated markups.

We’re here to help you manufacture your machined parts efficiently and timely. We understand the importance of getting your product(s) to market before your competitors do. We’re ready to accelerate your innovation.