Wrought Alloys

- Coppers: C10100 – C15999

- High Copper Alloys: C16000 – C19999

- Brasses: C20000 – C49999

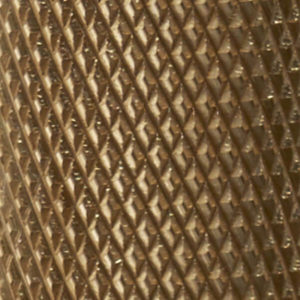

- Bronzes: C50000 – C69999

- Copper Nickels: C70000 – C73499

- Nickel Silvers: C73500 – C79999

Wrought copper alloys are processed by mechanical working such as rolling, extruding, or drawing. They are typically used in electrical, architectural, and industrial applications where high conductivity and ductility are required.