How Do Drilling and Tapping Benefit Your Supply Chain?

There are many benefits of drilling and tapping for your supply chain.

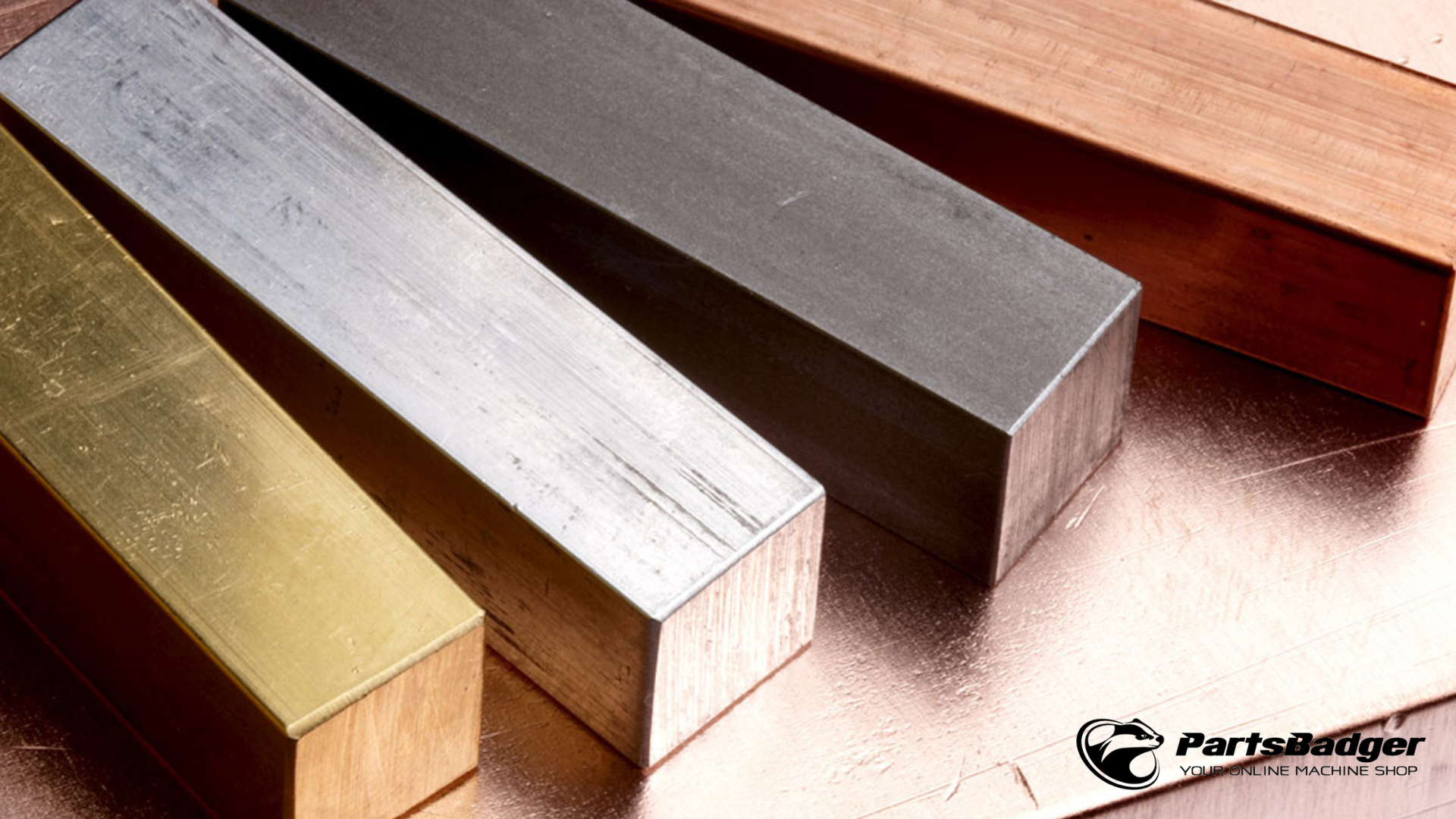

Drilling is the act of using a machine to create holes in certain materials, while tapping is the act of creating threads on materials like wood or metal so that you can screw them together. These both have benefits for your supply chain.

How Drilling Reduces Inventory

Inventory is costly to carry. It’s one of your supply chain’s biggest expenses. Reducing inventory can result in big savings, but it’s not always easy to tell if you have too much on hand or if you should carry more.

Drilling reduces inventory by allowing you to easily reorder parts. If a supplier sees that you’re using fewer parts of a certain type, they may be able to give you a better price on that part. Drilling also reduces inventory in another way: manufacturers typically produce only one or two versions of that particular product.

When you drill, it reduces inventory because when an item is sold out of stock, a manufacturer will produce another one only if there’s an order for it. That means that each time a customer purchases one of those items from you, it keeps them in business to produce more. So if customers can’t purchase that part from you when they need it, they have no reason to call or order from them.

How Tapping Reduces Inventory

There’s a significant difference between tapping and drilling. Tapping reduces inventory because it allows you to install smaller screws than drilling, meaning you use less material. This saves you time and money in both labor and material costs.

The only real downside is that tapping takes more time—but even with additional labor costs, tapping will save you overall. Tapping may be more expensive up front, but its benefits outweigh drilling due to its ability to reduce the inventory of manufactured goods.

How Drilling and Tapping Improves Supply Chain Visibility

By using drilling and tapping to gain greater visibility into your company’s operations, you can pinpoint bottlenecks in manufacturing, delivery, and quality control. When a company drills and taps a hole, it has to be done right. While all of us know that tapping a hole isn’t easy, there are methods to improve visibility throughout your supply chain.

The benefits are multifold: You can take steps to mitigate bottlenecks before they occur; improve the efficiency of operations; prevent errors or waste in product delivery; raise customer satisfaction by reducing delays or poor-quality products; reduce costs due to process improvements or scale efficiencies. Drill down on these benefits to further increase returns from an existing T&M operation.

PartsBadger will do all of that for you. We can help reduce all of these costs for you.

How Drilling and Tapping Saves Time, Labor, and Money

Drilling and tapping holes in a variety of different materials offer many benefits to both consumers and manufacturers. Drilling improves performance while reducing maintenance costs, saving time, labor, energy, and money.

A drill bit is typically made of a material such as tungsten carbide, steel, or cobalt. By cutting through a variety of materials, drill bits significantly reduce labor, which saves both time and money while improving performance. When it comes to taps, their helical-shaped edges are designed to create smooth interior threads while removing less material than other threading methods.

How Drilling Boosts Safety

Drilling ensures that stock is strong, safe, durable, and reliable. Every time you drill a hole in a piece of wood you are improving its strength by removing it weak and strengthening it. The location of holes can also have an impact on stability. Engineers drill holes to support structures and parts that would not otherwise be able to support themselves. This is to avoid failing at critical points where failure would pose a risk to human life or equipment.

Drilling operations, whether done manually or with a specialized drill machine, will result in holes that are perfect for use with whatever attachment you are using it for. These pre-drilled holes will also ensure that there is minimal material wasted or lost during operation. Using up less wood to be more efficient might not seem like a big deal at first, but when considering every part of your supply chain, every bit counts.

How Tapping Boosts Safety

Tapping a hole in a component doesn’t just leave it looking pretty. There are important advantages that come with it. For example, tapped holes improve machine safety. Why? Because they intend to keep manufacturing hardware attached to moving equipment. In other words, they prevent parts from flying off during production or transportation. This minimizes incidents of injury, which is particularly important when these parts would cause harm if they made contact with a person or other object in their vicinity.

Conclusion

All in all, each of these steps is important to keeping your company’s supply chain running smoothly. From sourcing materials to make sure shipments are safe and secure, each step along a supply chain is vital.

There are so many ways a simple mistake can completely ruin an entire production cycle. With constant diligence and attention to detail, there’s no reason why you should be caught off guard by such things.