PartsBadger Serves the Aerospace Industry

Prototyping and production runs are available in a number of materials best suited for aerospace technology. Material Certification, Certificate of Conformance and First Article Inspection are available options on all orders.

PartsBadger Production is ISO 9001:2015 and AS9100D Certified, providing the highest level of quality standard expected from the aerospace industry. Compliance with the industry standards is a key component to success.

Aerospace is a high technology industry that requires high tolerances and on-spec machined parts. PartsBadger is committed to providing quality assurance through investment in our quality control department and our quality certifications. We manufacture parts for aircraft, missiles, rockets, and spacecraft. Check out our capabilities and material pages to learn more of our offerings.

We believe ordering custom parts ought to be simple, fast, and straightforward. When we designed and created our Instant Quote system, we began with the goal of making prices available right away. We know that getting a price on your part without having to wait allows you to move faster, which means your ideas move forward. Let PartsBadger become a part of your supply chain as Your Online CNC Machine Shop.

Rapid Quote

Enter your material, finish, tolerance, quantity, and upload your file to get your own custom quote in 2-6 hours. The Rapid Quote is perfect for higher volumes or special features.

Quick Quotes

Competitive Prices

No Minimums

PartsBadger is Trusted by

Precision, Quality and Affordability at any volume

Our Modern CNC machines can handle small radius cuts and maintain a high quality level whether you want one piece or one hundred. Chamfered edges, multi radius curves, and tapped holes are a few things that make machining a part more workable for any projects. We take pride in making quality, custom, low cost, machined parts.

No limitations on materials here

Check our full list of materials available at PartsBadger. With no restrictions on materials, our Online Machining Service has you covered no matter what you need us to machine. There are also no limitations on quantity, we feel high quality, machined parts should be affordable when ordering 1 or 5,000.

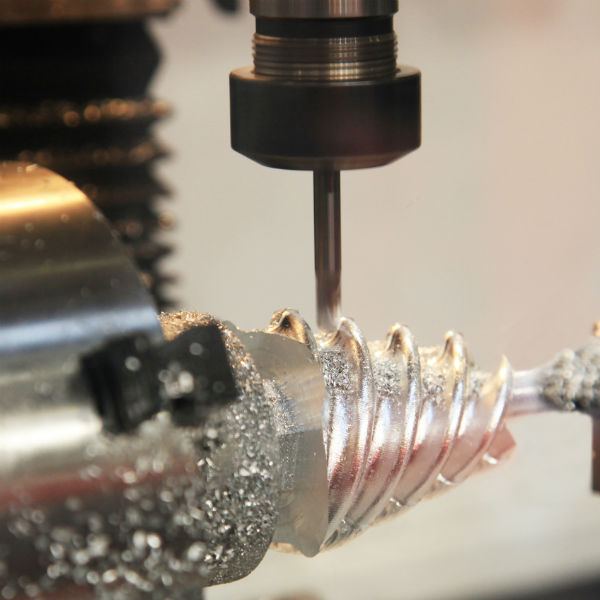

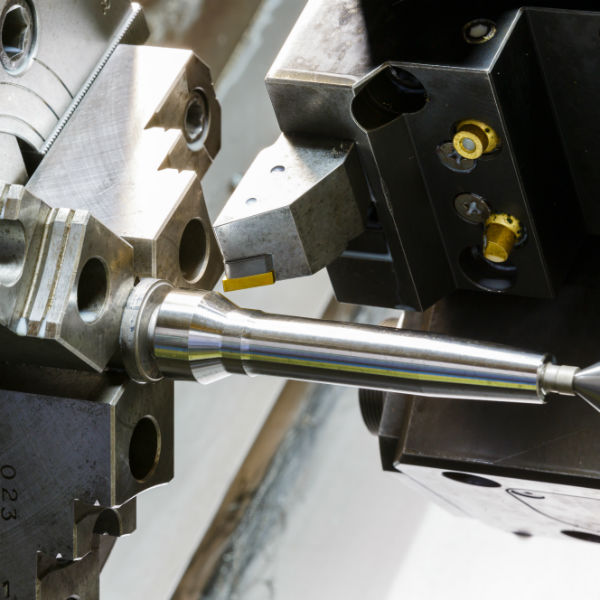

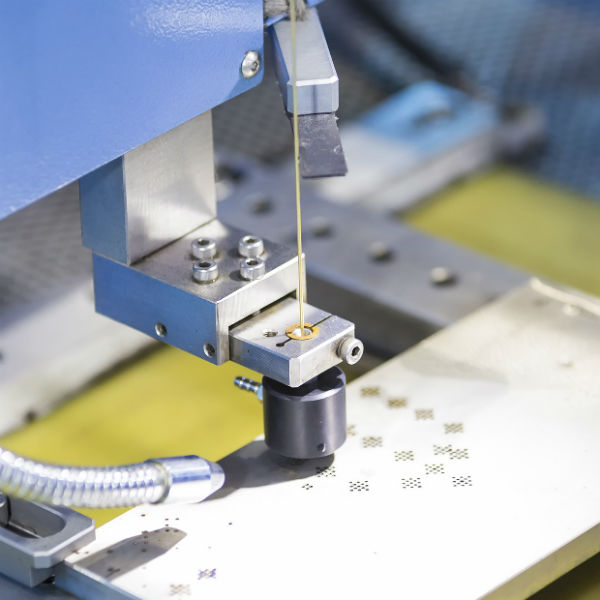

Types of Machining

PartsBadger offers a number of different machining methods to create your parts. Using a wide variety of machines PartsBadger is able to create simple and complex parts at the required tolerance and the best possible price.

3-Axis Milling

4 & 5-Axis Milling

Turning

Wire EDM

Small Hole EDM

Sinker EDM

Accelerate Your Innovation

We’re here to help you manufacture your machined parts efficiently and timely. We understand the importance of getting your product(s) to market before your competitors do. We provide quotes in hours and most parts in 14-Days or less. Use the form to reach our specialists to request a quote, check on an order status, or to learn more about us and our capabilities. We’re ready to accelerate your innovation.